Introduction

Manufacturing parts for production – also known as end-use parts – refers to the process of using raw materials to create a part that is designed and manufactured to be used in a final product, as opposed to a prototype or model. Check out our guide to manufacturing initial prototypes to learn more about this.

To ensure your parts function in a real-world environment – as machinery parts, vehicle components, consumer products, or any other functional purpose – manufacturing needs to be approached with this in mind. To successfully and efficiently manufacture parts for production, you should consider materials, design, and production methods to ensure you meet the necessary functional, safety, and quality requirements.

Selecting materials for production parts

Common materials for parts meant for production include metals such as steel or aluminum, plastics such as ABS, polycarbonate, and nylon, composites such as carbon fiber and fiberglass and certain ceramics.

The right material for your end-use parts will depend on the specific requirements of the application, as well as its cost and availability. Here are a few common properties to consider when selecting materials with which to manufacture parts for production:

-

Strength. Materials should be strong enough to withstand the forces to which a part will be exposed during use. Metals are good examples of strong materials.

-

Durability. Materials should be able to withstand wear and tear over time without degrading or breaking down. Composites are known for both durability and strength.

-

Flexibility. Depending on the application of the final part, a material may need to be flexible to accommodate movement or deformation. Plastics such as polycarbonate and nylon are known for their flexibility.

-

Temperature resistance. If the part will be exposed to high temperatures, for example, the material should be able to withstand the heat without melting or deforming. Steel, ABS, and ceramics are examples of materials that exhibit good temperature resistance.

Manufacturing methods for parts for production

Four types of manufacturing methods are used to create parts for production: subtractive manufacturing, additive manufacturing, metal forming, and casting.

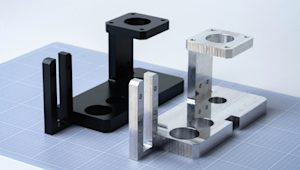

Subtractive manufacturing

Subtractive manufacturing – also known as traditional manufacturing – involves removing material from a larger piece of material until a desired shape is achieved. Subtractive manufacturing is often faster than additive manufacturing, making it more suitable for high-volume batch production. However, it can be more expensive, especially when considering tooling and setup costs, and generally produces more waste.

Common types of subtractive manufacturing include:

-

Computer numerical control (CNC) milling. A type of CNC machining, CNC milling involves using a cutting tool to remove material from a solid block to create a finished part. It is able to create parts with high degrees of accuracy and precision in materials such as metals, plastics, and composites.

-

CNC turning. Also a type of CNC machining, CNC turning uses a cutting tool to remove material from a rotating solid. It is typically used to create objects that are cylindrical, such as valves or shafts.

-

Sheet metal fabrication. In sheet metal fabrication, a flat sheet of metal is cut or formed according to a blueprint, usually a DXF or CAD file.

Additive manufacturing

Additive manufacturing – also known as 3D printing – refers to a process in which material is added atop itself to create a part. It is able to produce highly complex shapes that would otherwise be impossible with traditional (subtractive) manufacturing methods, generates less waste, and can be faster and less expensive, especially when producing small batches of complex parts. Creating simple parts, however, can be slower than subtractive manufacturing, and the range of available materials is generally smaller.

Common types of additive manufacturing include:

-

Stereolithography (SLA). Also known as resin 3D printing, SLA uses UV lasers as a light source to selectively cure a polymer resin and create a finished part.

-

Fused Deposition Modeling (FDM). Also known as fused filament fabrication (FFF), FDM builds parts layer by layer, selectively depositing melted material in a predetermined path. It uses thermoplastic polymers that come in filaments to form the final physical objects.

-

Selective Laser Sintering (SLS). In SLS 3D printing, a laser selectively sinters the particles of a polymer powder, fusing them together and building a part, layer by layer.

-

Multi Jet Fusion (MJF). As HP’s proprietary 3D printing technology, MJF can consistently and quickly deliver parts with high tensile strength, fine feature resolution, and well-defined mechanical properties

Metal forming

In metal forming, metal is shaped into a desired form by applying force through mechanical or thermal methods. The process can be either hot or cold, depending on the metal and the desired shape. Parts created with metal forming typically feature good strength and durability. Also, there is typically less material waste created than with other forms of manufacturing.

Common types of metal forming include:

-

Forging. Metal is heated, then shaped by applying compressive force to it.

-

Extrusion. Metal is forced through a die to create a desired shape or profile.

-

Drawing. Metal is pulled through a die to create a desired shape or profile.

-

Bending. Metal is bent to a desired shape via an applied force.

Casting

Casting is a manufacturing process in which a liquid material, such as metal, plastic, or ceramic, is poured into a mold and allowed to solidify into a desired shape. It is used to create parts that feature high degrees of accuracy and repeatability. Casting is also a cost-effective choice in large-batch production.

Common types of casting include:

-

Injection molding. A manufacturing process used to produce parts by injecting molten material – often plastic – into a mold. The material is then cooled and solidified, and the finished part is ejected from the mold.

-

Die casting. In die casting, molten metal is forced into a mold cavity under high pressure. Die casting is used to produce complex shapes with high accuracy and repeatability.

Design for manufacturability and parts for production

Design for manufacturing or manufacturability (DFM) refers to an engineering method of creating a part or tool with a design-first focus, enabling a final product that is more effective and cheaper to produce. Protolabs Network's automatic DFM analysis enables engineers and designers to create, iterate, simplify, and optimize parts before they are made, making the entire manufacturing process more efficient. By designing parts that are easier to manufacture, production time and costs can be reduced, as can the risk of error and defects in final parts.

Tips for using DFM analysis to minimize the costs of your production run

-

Minimize components. Typically, the fewer components a part has, the lower the assembly time, risk or error, and overall cost.

-

Availability. Parts that can be manufactured with available production methods and equipment – and that feature relatively simple designs – are easier and cheaper to produce.

-

Materials and components. Parts that use standard materials and components can help reduce costs, simplify supply chain management, and ensure that replacement parts are easily available.

-

Part orientation. Consider the orientation of the part during production. This can help minimize the need for supports or other additional features that can increase overall production time and cost.

-

Avoid undercuts. Undercuts are features that prevent a part from being easily removed from a mold or fixture. Avoiding undercuts can help reduce production time and costs, and improve the overall quality of a final part.

The cost of manufacturing parts for production

Striking a balance between quality and cost is key in manufacturing parts meant for production. Here are several cost-related factors to consider:

-

Materials. The cost of raw materials used in the manufacturing process depends on the type of material used, its availability, and the quantity required.

-

Tooling. Including cost of machinery, molds, and other specialized tools used in the manufacturing process.

-

Production volume. In general, the greater the volume of parts you produce, the lower the cost per part. This is especially true of injection molding, which offers significant economies of scale for larger order volumes.

-

Lead times. Parts produced quickly for time-sensitive projects often incur a higher cost than those with longer lead times.

Get an instant quote to compare pricing and lead times for your production parts.

To create a part meant for production, upload a CAD file to receive a free quote and comprehensive DFM analysis.

You can learn more about manufacturing parts for production on our Knowledge Base, or contact networksales@protolabs.com for personalized advice about your project.

Frequently asked questions

How do you manufacture parts for production?

Parts for production are most commonly created with subtractive manufacturing, additive manufacturing, metal forming, and casting.

What are the benefits of subtractive manufacturing?

The benefits of subtractive manufacturing include accuracy, precision, and a wide range of material options. It also allows engineers to work with materials at low temperatures, reducing the risk of loss of mechanical strength in parts.

What are the benefits of casting?

The benefits of casting include the ability to create complex parts that feature high accuracy and repeatability. It is also a cost-effective solution for large-batch production.

What are the benefits of metal forming?

The benefits of metal forming include the ability to create parts that are high in strength and durability. It is also a cost-effective choice for large-batch production.

What are the benefits of additive manufacturing?

The benefits of additive manufacturing include the ability to create complex geometries and customized parts quickly and efficiently.

Is manufacturing parts for production expensive?

Manufacturing parts for production requires investment in equipment and materials, however, there are ways to reduce your costs, such as using Protolabs Network's DFM analysis to optimize your design for cost-efficient production. Keep in mind that for many manufacturing methods, such as injection molding, the cost per part declines as the order volume increases.

How can you cut costs of manufacturing parts for production?

You can lower the costs of manufacturing parts for production by optimizing manufacturing processes, reducing waste, streamlining supply chain and logistics, and using efficient technologies.