Introduction

Consumer products encompass a diverse range of goods that are designed for use by individuals or households. They include various items used for personal care, home and kitchen, electronics, entertainment, and more. Of course, the actual list of consumer products is much too long to list here, but here are a few broad categories that often interest Protolabs Network's customers.

-

Home and kitchen appliances

-

Furniture and home décor

-

Sports and fitness equipment

-

Toys and games

Creating a consumer product involves several important steps to ensure its successful development and manufacturing. Find out exactly how consumer products are created, the methods and materials used to create them, and tips for design that will increase the efficacy and success of your final products.

What are the steps of manufacturing a consumer product?

While the specific steps – and their order – may vary depending on the product and industry, there are several general steps that nearly every product goes through before it is produced.

-

Defining requirements. Often, the first step of consumer product manufacturing is defining what the customer wants or needs, then breaking that down into functional requirements. For example, should consumers want a fast car, the functional requirements will revolve around high maximum speeds and acceleration.

-

Product design. Once you have an idea for a product, the next step is to design it. This involves creating detailed specifications, sketches, or digital models that outline the product's functionality, features, and aesthetics

-

Prototype development. Building a prototype allows you to test and refine your product design. This can be done using rapid prototyping techniques such as 3D printing or by creating a small batch of products for testing and evaluation.

-

Testing and Iteration. The prototype undergoes rigorous testing to ensure it meets the desired functionality, performance, and safety standards – as well as to determine if it is what the customer actually wants. Feedback from users, focus groups, or beta testing can help identify areas for improvement.

-

Material sourcing. Once the design is finalized, the necessary materials and components for manufacturing need to be sourced. This may involve researching suppliers, negotiating contracts, and ensuring the quality and availability of materials.

-

Manufacturing process selection. Choosing the right manufacturing process is crucial to achieve efficient and cost-effective production. Options include injection molding, machining, 3D printing, or a combination of various techniques.

-

Production. The product moves into full-scale production, where it is sometimes manufactured in large quantities based on demand forecasts and market needs. Continuous monitoring and quality control are essential during this phase.

-

Packaging and branding. Packaging plays a crucial role in attracting consumers and protecting the product during storage and transportation. Developing an appealing and informative package design, along with branding elements, helps establish a strong market presence.

What manufacturing methods are used to create consumer products?

The right manufacturing method for your product will depend on factors such as the product type, desired quality, production volume, cost considerations, and material properties. A combination of manufacturing methods is often involved. Here are a few of the most common and their uses.

-

Injection molding. Components for consumer products, such as casings, enclosures, handles, buttons, knobs, and structural parts, are commonly produced through injection molding. Injection molding is also useful for large quantities of consumer products, as well as those for which aesthetics is a requirement.

-

Sheet metal fabrication. Parts for consumer goods that require high strength and precision are often created with sheet metal fabrication. Examples include chassis, brackets, frames, panels, enclosures, and structural components in products ranging from appliances to electronics.

-

Casting. Used to create metal components such as engine parts or jewelry, as well as ceramic objects like pottery and decorative tiles, and plastic parts for various consumer products like toys, packaging, and electronic enclosures.

-

Forming. Used to create metal consumer products such as automobile panels, beverage cans, kitchen utensils, and household appliances like ovens and refrigerators.

-

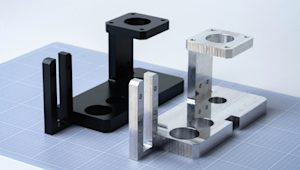

Machining. Commonly used for metal consumer products, as it allows for precise shaping and finishing of tools, automotive parts, computer hardware, and intricate mechanical parts.

-

Additive manufacturing (3D printing). Because it enables the production of complex shapes and prototypes with relatively less waste material, 3D printing is often used to create consumer products such as customized jewelry, medical implants. Additionally, 3D printing is a go-to technology for prototyping, due to its ability to quickly and cheaply create small batches of parts that are easily modified and post-processed.

Which materials are used to manufacture consumer products?

Metals, plastics, composites, ceramics, and elastomers are commonly used to manufacture consumer products. The specific choice of materials depends on the necessary strength, durability, thermal properties, chemical resistance, electrical properties, and other specific application requirements. Manufacturers often select a combination of materials to achieve the desired performance and functionality.

What metals are used to manufacture consumer products?

Metals are used in consumer products for their strength, durability, electrical conductivity, thermal properties, and aesthetic appeal.

-

Steel. Commonly used in the manufacturing of consumer products due to its strength, durability, and versatility. It is found in appliances, automotive parts, tools, furniture, and construction materials – as well as in products used in the medical industry, due to aluminum’s neurotoxicity.x

-

Aluminum. Lightweight, corrosion-resistant, aluminum also has excellent thermal conductivity. It is used in consumer products like cookware, beverage cans, window frames, bicycles, and electronics, where a balance of strength and weight is desired.

Copper. Valued for its excellent electrical conductivity, copper is ideal for electrical wiring, connectors, and electronic components. It is also used in plumbing fixtures, cookware, and decorative items due to its aesthetic appeal and antimicrobial properties.

What plastics and polymers are used to manufacture consumer products?

Plastics are used to manufacture consumer products due to their versatility, cost-effectiveness, lightweight properties, durability, and ease of customization.

-

Polyethylene (PE). Widely used in consumer products due to its versatility, durability, and low cost. It is used in packaging materials, plastic bags, bottles, toys, and household products.

-

Polypropylene (PP). A popular plastic known for its high chemical resistance, stiffness, and heat resistance. PP is used in consumer products such as food containers, automotive parts, medical devices, and textiles.

-

Polyvinyl Chloride (PVC). A versatile plastic used in a wide range of consumer products, PVC is found in pipes, window frames, flooring, cables, medical tubing, and various household items due to its durability and cost-effectiveness.

What elastomers and ceramics are used to manufacture consumer products?

Elastomers are used to create consumer products because they are flexible, durable, and temperature-resistant. Ceramics, meanwhile, are chosen for their aesthetic appeal, strength, and heat resistance.

-

Silicone. Used to manufacture consumer products due to their flexibility, durability, and temperature resistance. Silicone is often used in seals, gaskets, O-rings, and other components requiring elasticity and reliable performance.

-

Porcelain. A type of ceramic commonly used in consumer product parts for its aesthetic appeal, strength, and resistance to heat. Porcelain is used to create used items such as tableware, decorative accessories, and bathroom fixtures.

-

Zirconia. Offering exceptional strength, durability, and biocompatibility, zirconia is used in consumer products such as ceramic knives, jewelry, and high-end watches.

Design for manufacturability and parts for production

Design for manufacturability (DFM) plays a crucial role in the production of consumer products. By incorporating DFM principles into the design process, engineers and designers can create products that are easier and more cost-effective to manufacture.

Protolabs Network's DFM analysis, which is built into our online quoting system, enables a thorough evaluation of part designs, allowing for iteration, simplification, and optimization before manufacturing begins. This proactive approach ensures that potential issues and inefficiencies are addressed early on, resulting in a more efficient manufacturing process that ultimately leads to improved quality, increased productivity, and greater customer satisfaction.

Here are a few tips for using DFM analysis to minimize the costs of your consumer products.

-

Involve manufacturing experts early. Engage with manufacturing experts during the design phase to identify potential manufacturing issues and optimize the product design for cost-effective production.

-

Simplify designs. Minimize complexity by reducing the number of components, using standard parts, and avoiding intricate features that could increase manufacturing costs.

-

Optimize material selection. Select materials that are readily available, cost-effective, and suitable for the manufacturing process, while still meeting the product's performance and quality requirements.

-

Design for efficiency. Consider the capabilities and limitations of the chosen manufacturing methods and design the product to maximize efficiency, minimize waste, and streamline production processes.

-

Consider scalability and automation. Design with scalability in mind, ensuring the product can be manufactured efficiently at different production volumes. Additionally, explore opportunities for automation to reduce labor costs and increase production speed.

Find out more about manufacturing end-use parts as well as how Protolabs Network helps engineers produce custom parts for consumer products such as electronics.

When you’re ready to get started, upload a CAD file for a no-obligation quote and lead times.

Frequently asked questions

How long does it typically take to manufacture a consumer product?

The manufacturing time varies depending on factors like complexity, production volume, and the manufacturing method used, but it can range from a few days to several weeks.

What factors impact the cost of manufacturing consumer products?

This depends on material selection, production volume, the manufacturing method, lead times and the complexity of the product.

How can I ensure the quality of manufactured consumer products?

Implementing rigorous quality control processes, conducting inspections at different stages of production, and working with reliable suppliers and manufacturers who have a proven track record can help ensure the quality of manufactured consumer products. Find out about Protolabs Network's quality control procedures.

What is the role of prototypes in consumer product manufacturing?

Prototypes allow for testing and validation of the design, functionality, and manufacturability of a product before mass production. They help identify and address potential issues and optimize the final product.

Can I customize consumer products during manufacturing?

Customization is possible, but it may affect the cost and lead time required to manufacture your part. As well as all of the capabilities available via the Protolabs Network's platform, you can also contact us about custom requests.