What is TPU?

Thermoplastic polyurethane (TPU) is a thermoplastic elastomer that is commonly used in injection molding and 3D printing. It is a rubber-like material with a low shore hardness of 85-95A, meaning it is relatively hard, but still flexible. This is greatly beneficial in many of its applications.

What are the properties of TPU?

TPU has many properties that make it a good choice for industrial applications.

-

Flexibility and elasticity. TPU is flexible, and can bend before breaking.

-

Tensile strength. TPU has excellent tensile strength, which means it can withstand a great amount of stretching or pulling.

-

Abrasion resistance. TPU has high abrasion resistance, which makes it a good choice for applications that involve large amounts of friction and wear.

-

Impact resistance. TPU can absorb and dissipate energy from impacts, which helps parts maintain their structural integrity under hardworking conditions.

-

Chemical resistance. TPU is resistant to oils, greases, and many solvents, which helps in maintaining its performance in automotive and manufacturing applications.

-

Cold flexibility. TPU maintains its flexibility even at low temperatures, meaning it will not become brittle in cold conditions.

-

Hydrolysis resistance. Some TPUs offer good resistance to hydrolysis – a chemical reaction in which water breaks down a compound – making them suitable for applications involving prolonged exposure to water or high humidity.

-

Electrical insulation. Some types of TPU can be effective at electrical insulation, making it suitable for use in electronic applications.

What are the types of TPU?

TPU is a copolymer, and can be combined with different chemical units.There are three main types of TPU: polyester, polyether, and polycaprolactone. While similar, they exhibit a few key differences in properties, which make them suited to slightly different types of applications.

-

Polyester-based TPUs have high mechanical strength, excellent abrasion and chemical resistance, and are commonly used in industrial applications, as well as to create shoes and other footwear.

-

Polyether-based TPUs are great in low-temperature environments, with good hydrolysis resistance. They are most commonly used in medical devices, automotive parts, and underwater applications.

-

Polycaprolactone-based TPUs are biodegradable, with lower melting points and better processability than other types of TPU. They are best-suited for 3D printing and medical implants.

What post-processing techniques do you use for TPU?

The following are a few ways that TPU can be post-processed.

-

Annealing. With annealing, TPU parts are heated to temperatures below their melting point, then gradually cooled. This can improve TPU’s strength and elasticity even further, while reducing warping and stress.

-

Sanding. Using fine-grit sandpaper to sand TP U parts can reduce layer lines and imperfections, resulting in a smoother surface finish.

-

Chemical smoothing. Solvents like isopropyl alcohol (IPA) or tetrahydrofuran (THF) can dissolve the outer layer of TPU parts to achieve a smoother surface finish that has a glossy appearance.

-

Coating. Applying coatings or sealants to TPU parts can improve a their durability, water resistance, and UV resistance.

What are best practices for designing parts with TPU?

Here are a few factors to consider when creating parts with TPU.

-

Account for shrinkage. TPU may shrink when it cools, and its shore hardness may increase as it gets colder. Be sure to plan for this in your design to ensure a part’s dimensional accuracy.

-

Optimize wall thickness. You can design TPU parts with different wall thicknesses to balance strength and flexibility. Thicker walls are typically stronger, while thinner walls are more flexible. However, you should avoid sudden changes in wall thickness to prevent undue stress on your parts.

-

Use rounded corners. By designing parts with rounded corners and fillets rather than sharp edges, your part can distribute stress more evenly and reduce the likelihood of stress concentrations and tearing.

-

Incorporate draft angles. If you are using TPU in an injection-molded part, you may want to add draft angles to features such as sidewalls and overhangs, so it can be more easily ejected from a mold.

-

Minimize undercuts. Minimizing undercuts in your design can also help a part eject from a more more easily. Alternativley, you can consider using side actions or sliders for complex geometries if undercuts are unavoidable.

-

Overmolding. When used in injection molding, TPU can be overmolded onto rigid substrates to create parts with soft-touch surfaces or integrated seals.

When should you use TPU?

Engineers typically use TPU for the following types of custom parts.

Flexible parts

TPU's high elasticity and flexibility make it ideal for producing parts that need to bend, stretch, or flex without breaking. This makes TPU a great choice for:

-

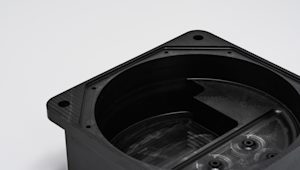

Seals, gaskets, and O-rings in automotive and industrial applications

-

Protective cases and covers for electronic devices and consumer goods

-

Flexible tubing and hoses for fluid transfer in medical and industrial settings

Impact-resistant components

TPU's impact resistance make it suitable for parts that are subjected to repeated stress or intense vibrations. For example, you can use TPU to create:

-

Bumpers and protective covers for electronic devices and handheld tools

-

Cushioning and shock-absorbing components in footwear and automotive applications

-

Protective padding in sports equipment and safety gear

Wear-resistant products

TPU's excellent abrasion resistance makes it suitable for parts that come into contact with abrasive surfaces or undergo repetitive wear. Applications here might include:

-

Conveyor belts and belting systems in manufacturing environments

-

Rollers, wheels, and pulleys in industrial equipment and machinery

-

Soles and outsoles for footwear

Soft-touch and gripping surfaces

TPU's has a soft texture and grippy surface that makes it a good choice for applications where a comfortable and secure grip is important. These applications include:

-

Handles, grips, and ergonomic tools

-

Overmolded grips on handles and control surfaces

-

Buttons and surfaces on electronic devices and appliances

Medical and healthcare

TPU's biocompatibility, flexibility, and durability make it suitable for a wide range of medical and healthcare applications. TPU can be used to create:

-

Medical tubing and catheters

-

Orthopedic braces, supports, and splints

-

Prosthetic components and wearable medical devices

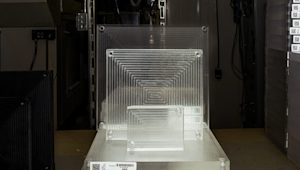

Custom protoypes and one-off parts

Because you can use TPU in 3D printing, it is a great choice for rapid prototyping and on-demand manufacturing of custom parts with complex geometries. You can use TPU to create:

-

Prototypes for product design and development

-

Custom insoles and orthotics

-

Functional prototypes for testing and validation in engineering

When you’re ready to create a part with TPU, upload a CAD file for an instant quote and automatic DFM analysis. You can also learn more about different types of manufacturing materials and find out how to select the best filament for 3D printing.

Frequently asked questions

Can TPU be sterilized?

Yes, TPU can be sterilized using methods such as autoclaving, making it good for use in medical applications.

What is the glass transition temperature (Tg) of TPU?

TPU's glass transition temperature typically ranges from -30°C to -50°C, influencing its flexibility and mechanical properties at different temperatures.

What are the typical printing temperatures for TPU?

Printing temperatures for TPU typically range from 200 °C to 230 °C for the extruder and 40 °C to 60 °C for the heated bed, depending on the type of TPU.

What are the key advantages of TPU over other flexible materials?

TPU offers excellent abrasion resistance, flexibility, and chemical resistance compared to other flexible materials.