3D printing requires more steps and considerations than you might think. One of these important factors—often overlooked by designers and engineers—is part orientation (also called build orientation). How you orient your parts in the printer will play a significant role in delivering the final quality you want from additive components.

This article covers how part orientation impacts accuracy, manufacturing time, strength and even surface finish quality. After reading this piece, you’ll never forget the importance of the build orientation ever again.

Curious about the cost of 3D printing custom parts?

Explore our 3D printing services Upload your CAD file for a free, instant quote

How does part orientation affect accuracy?

To understand how part orientation affects the accuracy of 3D-printed parts, consider the humble cylinder. Let’s say you’re using FDM to print a cylinder with a hole (10 mm outer diameter, 6 mm inner diameter, 30 mm length) with its center axis vertical. The 3D printer will construct this part as a series of concentric circles layered on top of one another, producing a final cylinder with a relatively smooth outer surface.

Suppose the same cylinder is reorientated with its center axis horizontally. The part will be built as a series of rectangles (with slightly different widths) layered on top of each other. Also, the surface of the cylinder that touches the build platform will be flat.

By orientating the part in different directions, there is a significant difference in the print quality.

How does part orientation affect print time?

Build orientation can also have a significant impact on print time.

Let’s use the cylinder from the previous section. In this case, the horizontal orientation will take significantly less time to print than the vertical, as the total number of layers is significantly reduced. At a 100 μm layer height, the horizontal cylinder will be printed with 100 total layers and the vertical with 300 layers. This can add up to significant time differences for large parts.

How does part orientation affect the strength of 3D-printed parts?

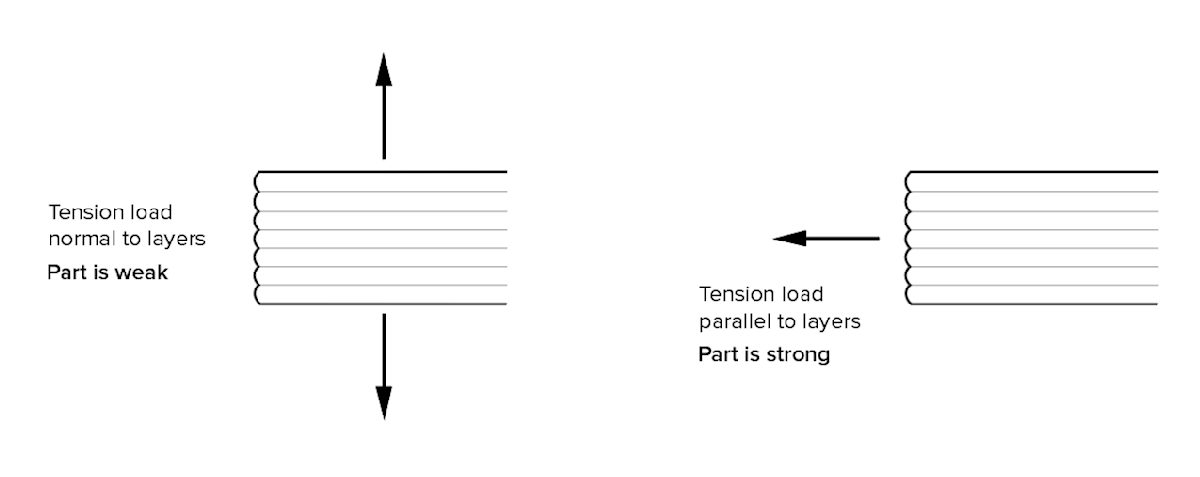

Some 3D printers (notably FDM) build parts that have inherently anisotropic properties, meaning they are much stronger in the XY direction than the Z direction.

For functional parts, it’s important to consider the application and the direction of the loads. For example, FDM parts are much more likely to delaminate and fracture when placed in tension in the Z direction compared to the XY directions (up to 4-5 times difference tensile strength).

How do support structures factor in with part orientation?

Support material adds extra time and cost to a 3D printing run. Often a lot of designing time is spent on the optimal part orientation to reduce the likelihood of print failure and the amount of required support.

Getting support structures right is definitely a 3D printing step that deserves a lot of thought. It's why we wrote a comprehensive guide on optimizing the use of support structures and materials.

How does part orientation affect surface finishes?

Generally, the top or upward-facing surfaces of a 3D-printed part will have the best surface finish, but this varies from process to process.

For FDM, the top surface is smoothed by the extrusion tip, the surface in contact with the print bed will usually be glossy and the surfaces above support structures will have support marks.

For SLA, the lower surfaces will have support marks and require post-processing, while the top surfaces will be smooth and free of support marks. Parts printed with a powder bed 3D printing processes, like SLS and MJF, will have a more grainy finish on their lower surfaces.

How important is part orientation for different 3D printers?

While part orientation is a crucial factor for some 3D printers, it’s not universally crucial. Certain 3D printing technologies can produce parts of pristine quality without the operator having to bother with how they orient the print.

For instance, part orientation and print quality go hand in hand if we’re talking about FDM or SLA. Powder-based technologies like SLS and MJF aren’t as reliant on build orientation as FDM, on the other hand, but it’s still an important consideration.

Frequently asked questions

What is part orientation in 3D printing?

Part orientation is an often crucial parameter in 3D printing, especially if you’re using additive technology for rapid prototyping, as it affects how fast and with what level of quality you can 3D print parts. The way you orientate parts will significantly influence your manufacturing productivity.

Will part orientation affect the cost of 3D printing?

The short answer is yes, part orientation will affect how expensive it is to 3D print parts. To explain it further, this has to do with the need for support structures. If you orientate your parts so there are significantly more overhangs and tricky angles, you’ll need to print with support materials, which will add to the final cost of your parts. Optimal part orientation will reduce the amount of material needed and the risk of print failure. This is most important for FDM and SLA.

Is it better to 3D print vertically or horizontally?

This will depend a bit on your design, but in general, printing horizontally will likely lead to shorter print times and fewer needs for support structures. We recommend orientating cylindrical features vertically for a smoother surface finish, though.

Which 3D printers produce isotropic parts?

If you want to produce isotropic parts, where the mechanical properties are the same in every direction, you have to opt for SLA or MJF.