The emergence of AI has been so fast-moving, so wide-ranging, and so disruptive in almost every industry, it’s clear that it’ll have an impact in the 3D printing space, too. The question is in which part of the process the technology will be most consequential. Of our survey respondents, 14% think AI will have the biggest impact by providing automated and accessible DFM at the slicer level; 23% think it will be the development of new materials and printing techniques; and 25% think AI will improve accessibility to non-planar FDM printing through improved slicer software. The largest group of the respondents, at 33%, see AI having the biggest impact at the hardware level, through enabling automated print tuning by leveraging computer vision and sensors.

“Like every industry today, 3D printing is capitalizing on the excitement around next generation AI and automation tools,” says François Minec, Global Head of 3D Polymers, HP Personalization and 3D Printing at HP. “Advancements in 3D hardware, firmware, and software are bringing data analytics and KPI monitoring to the forefront, enabling scalability for even more manufacturers.”

Adam Hecht, co-founder and director of Additive Manufacturing at DIVE, a design agency specialized in industrial additive manufacturing, agrees that it’s the hardware where AI is going to be most helpful. “Right now, we have a lot of smart printers that are very dumb. They will say something is wrong without specifying what it is. That’s very frustrating for a lot of consumers and companies. But as the systems get smarter, they can actually help users to self-diagnose, or dial in new materials, for example—I think that’s where we’re going to see a lot more adoption.”

“In terms of quality control, most of what I’ve seen has been in-process monitoring,” says Eric Utley, 3DP applications engineering manager at Protolabs. “There’s definitely research going on in that area, and I can certainly see it being offered commercially in the next couple of years.”

Alex Huckstepp, advanced-manufacturing expert and co-founder of a still-stealth manufacturing software startup, agrees. “Process control — anomaly detection and closed-loop feedback opportunities — would be a frontier where AI and machine learning could have an impact.”

When it comes to generative design, Hecht thinks AI’s impact may be more limited. “Generative design works fairly well in terms of topology optimization. But I wouldn’t say it’s too universally helpful, other than for very specific parts of the industry such as aerospace, automotive, or medical, that are creating very high-performance, lightweight parts. It works out really well in those.”

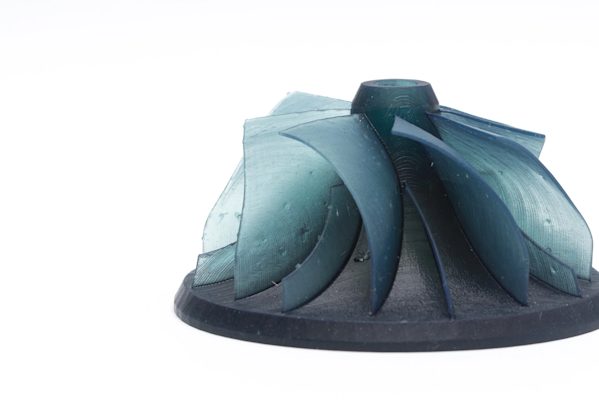

AI can also be helpful for consolidating the many elements of designing for 3D printing, from optimizing to adding lattices and surface textures such as basket weaves. “There’s so much you can do to a part because you have so much freedom in 3D printing,” says Hecht. AI-assisted programs can help with combining these elements in one step to make the design process easier.

“We’re starting to see interesting tools on the design side—designing within manufacturing process constraints in a much more automated, optimized way,” says Huckstepp. “Then there’s multiphysics process simulation—there’s some really interesting AI tools emerging there.”

“AI-generated CAD is accelerating quickly,” adds Utley. “And NASA have been promoting their software, which is much more manufacturing focused, and a lot of that that is really, really interesting.” The software generates optimized designs in line with the parameters specified by engineers. “It’s tuned towards specific manufacturing processes and is actually doing topology optimization,” Utley says.

But you don’t have to be working at NASA level for AI to be useful for you—in fact, the skill and constant practice required, for example, to be efficient with making 3D CADs means AI assistance can significantly accelerate and simplify these processes, not to mention present an appealing proposition to engineers who are less familiar in the design space. “I think an important factor stopping people from ordering 3D printing is not knowing how to design,” says Robin Brockötter, supply chain manager at Protolabs, “and I can imagine that AI will make this a lot easier.”

For more insights on the 3D printing industry including market data and future trends, download a copy of our 3D Printing Trend Report 2024.