The manufacturing & design guide

Injection molding

In this guide you’ll find everything you need to know about injection molding. Master the technology’s basic principles and learn actionable design tips fast that will save you time and cut costs.

Part 1

The basics of injection molding

What is a injection molding? How does it work and what is it used for?

In this section, we answer these questions and show you common examples of injection molded parts to help you familiarize yourself with the basic mechanics and applications of the technology.

What is injection molding?

Injection molding is a manufacturing technology for the mass-production of identical plastic parts with good tolerances. In Injection Molding, polymer granules are first melted and then injected under pressure into a mold, where the liquid plastic cools and solidifies. The materials used in Injection Molding are thermoplastic polymers that can be colored or filled with other additives.

Almost every plastic part around you was manufactured using injection molding: from car parts, to electronic enclosures, and to kitchen appliances.

Injection molding is so popular, because of the dramatically low cost per unit when manufacturing high volumes. Injection molding offers high repeatability and good design flexibility. The main restrictions on Injection Molding usually come down to economics, as high initial investment for the mold is required. Also, the turn-around time from design to production is slow (at least 4 weeks).

The injection molding process

Injection molding is widely used today for both consumer products and engineering applications. Almost every plastic item around you was manufactured using injection molding. This is because the technology can produce identical parts at very high volumes (typically, 1,000 to 100,000+ units) at a very low cost per part (typically, at $1-5 per unit).

But compared to other technologies, the start-up costs of injection molding are relatively high, mainly because custom tooling is needed. A mold can cost anywhere between $3,000 and $100,000+, depending on its complexity, material (aluminum or steel) and accuracy (prototype, pilot-run or full-scale production mold).

All thermoplastic materials can be injection molded. Some types of silicone and other thermoset resins are also compatible with the injection molding process. The most commonly used materials in injection molding are:

- Polypropylene (PP): ~38% of global production

- ABS: ~27% of global production

- Polyethylene (PE): ~15% of global production

- Polystyrene (PS): ~8% of global production

Even if we take into account all other possible manufacturing technologies, injection molding with these four materials alone accounts for more than 40% of all plastic parts produced globally every year!

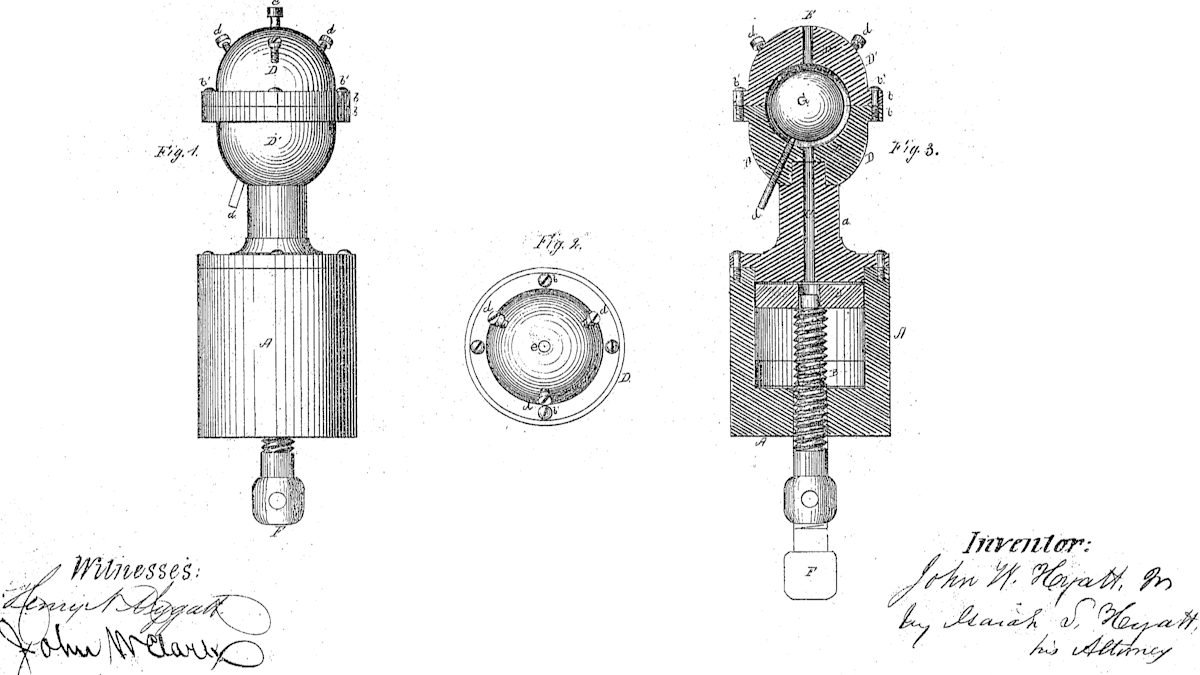

A brief history of Injection molding

Plastics replace ivory

In 1869, John Wesley Hyatt invented celluloid, the first practical artificial plastic intended to replace ivory for the production of… billiard balls! Early injection molding machines used a barrel to heat up the plastic and a plunger to inject it to the mold.

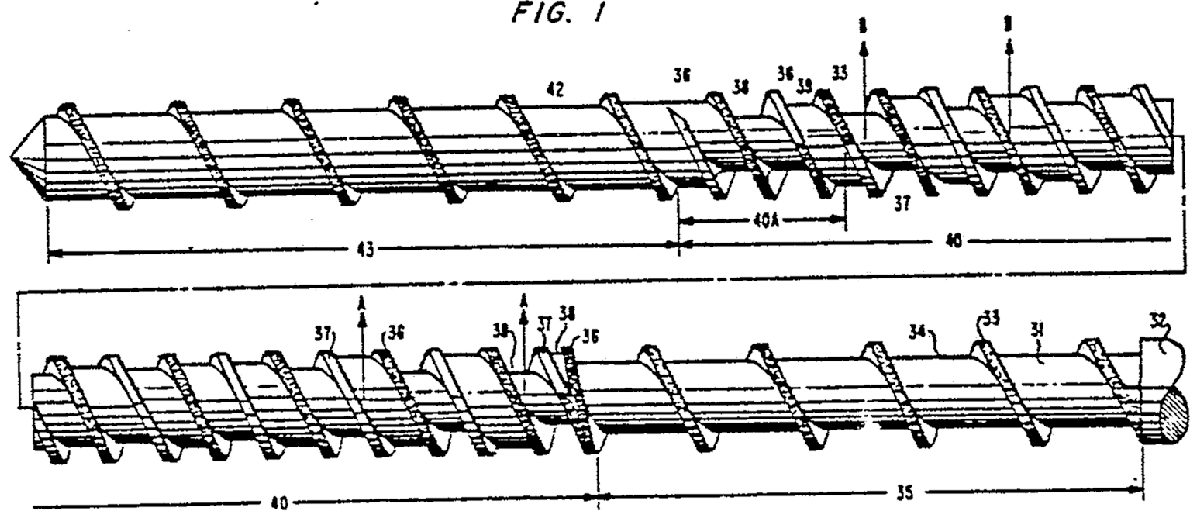

A revolutionary invention

In the mid 1950s, the invention of the reciprocating screw single-handedly revolutionized the plastics industry. The reciprocating screw solved key issues with uneven heating of the plastic that previous systems faced, and opened up new horizons for the mass production of plastic parts.

Injection molding today

Today, injection molding is a $300 billion market. 5+ million metric tons of plastic parts are produced with injection molding globally each year. Recently, the demand of biodegradable materials is increasing for environmental reasons.

Injection molding machines: how do they work?

An injection molding machine consists of 3 main parts: the injection unit, the mold - the heart of the whole process - and the clamping/ejector unit.

In this section, we examine the purpose of each of these systems and how their basic operation mechanics affect the end-result of the Injection molding process.

Watch a large injection molding machine in action while producing 72 bottle caps every 3 seconds in the video here:

The injection unit

The purpose of the injection unit is to melt the raw plastic and guide it into the mold. It consists of the hopper, the barrel, and the reciprocating screw.

Here is how the injection molding process works:

- The polymer granules are first dried and placed in the hopper, where they are mixed with the coloring pigment or the other reinforcing additives.

- The granules are fed into the barrel, where they are simultaneously heated, mixed and moved towards the mold by a variable pitch screw. The geometry of the screw and the barrel are optimized to help build up the pressure to the correct levels and melt the material.

- The ram then moves forwards and the melted plastic is injected into the mold through the runner system, where it fills the whole cavity. As the material cools down, it re-solidifies and takes the shape of the mold.

- Finally, the mold opens and the now solid part is pushed out by the ejector pins. The mold then closes and the process repeats.

The whole process can be repeated very fast: the cycle takes approximately 30 to 90 seconds depending on the size of the part.

After the part is ejected, it is dispensed on a conveyor belt or in a holding container. Usually, injection molded parts are ready to use right away and require little to no post-processing.

Manufacturing the mold

The mold is like the negative of a photograph: its geometry and surface texture is directly transferred onto the injection molded part.

It usually makes up the largest portion of the start-up costs in injection molding: the cost of a typical mold starts at approximately $2,000-5,000 for a simple geometry and relatively small production runs (1,000 to 10,000 units) and can go upwards to $100,000 for molds optimized for full-scale production (100,000 units or more).

This is due to the high level of expertise required to design and manufacture a high-quality mold that can produce accurately thousands (or hundreds of thousands) of parts.

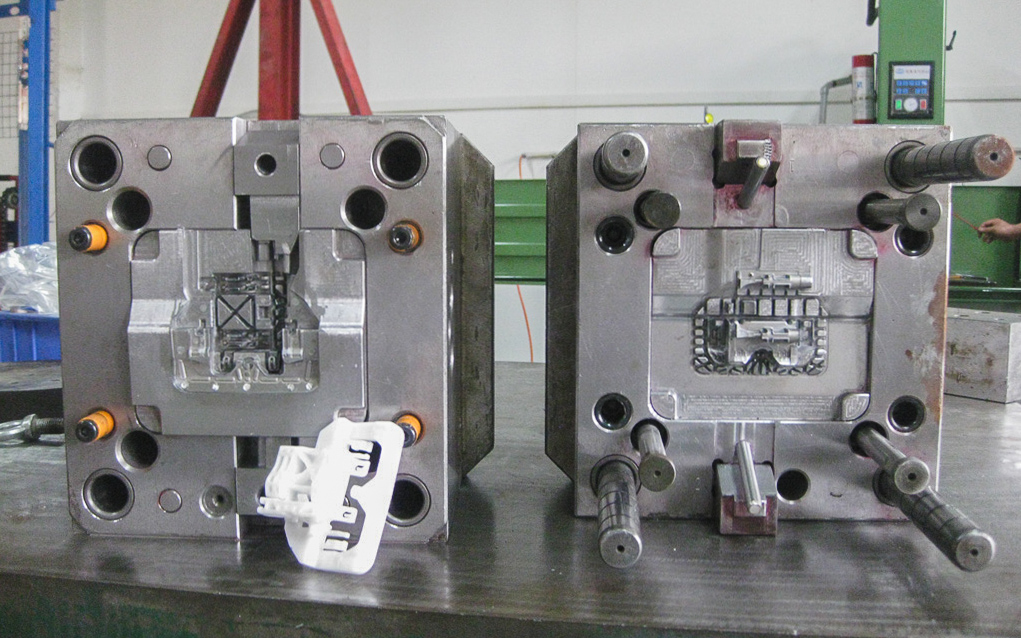

Molds are usually CNC machined out of aluminum or tool steel and then finished to the required standard. Apart from the negative of the part, they also have other features, like the runner system that facilitates the flow of the material into the mold, and internal water cooling channels that aid and speed up the cooling of the part.

Learn more about CNC machining in the manufacturing and design guide →

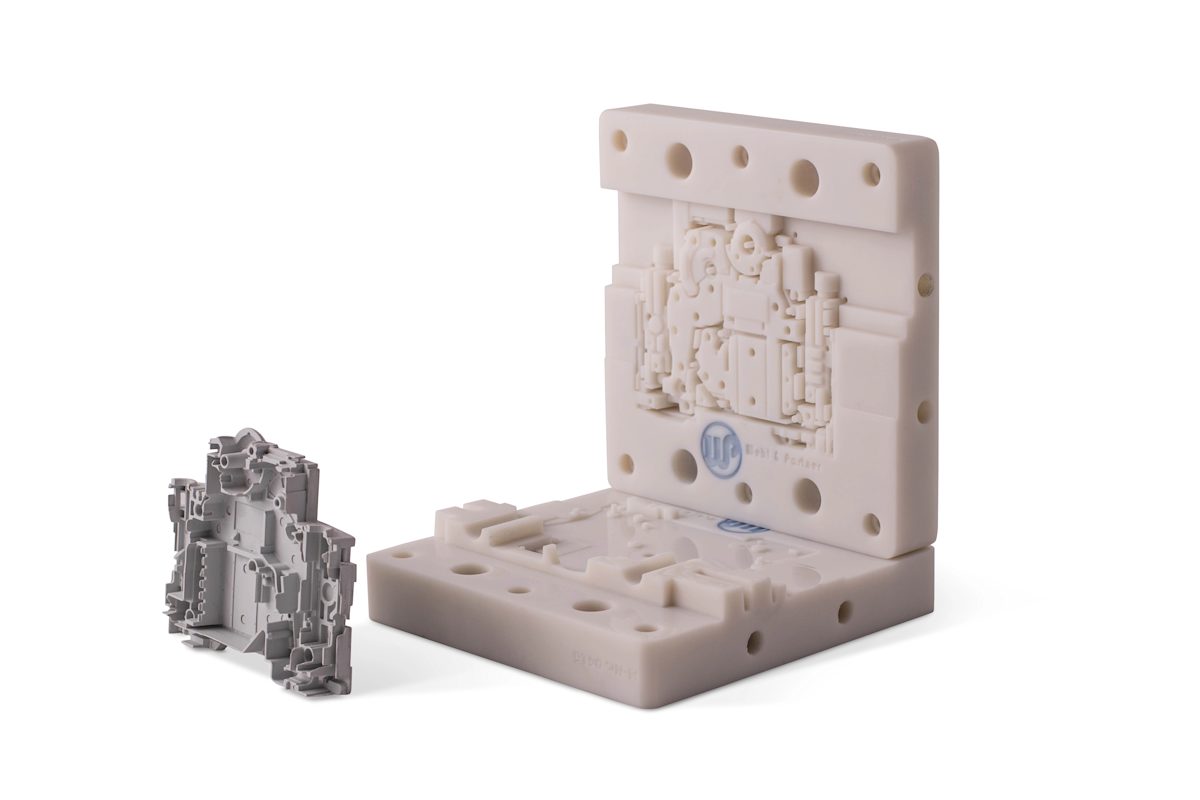

Recent advances in 3D printing materials have enabled the manufacturing of molds suitable for low-run injection molding (100 parts or less) at a fraction of the cost. Such small volumes were economically unviable in the past, due to the very high cost of traditional mold making.

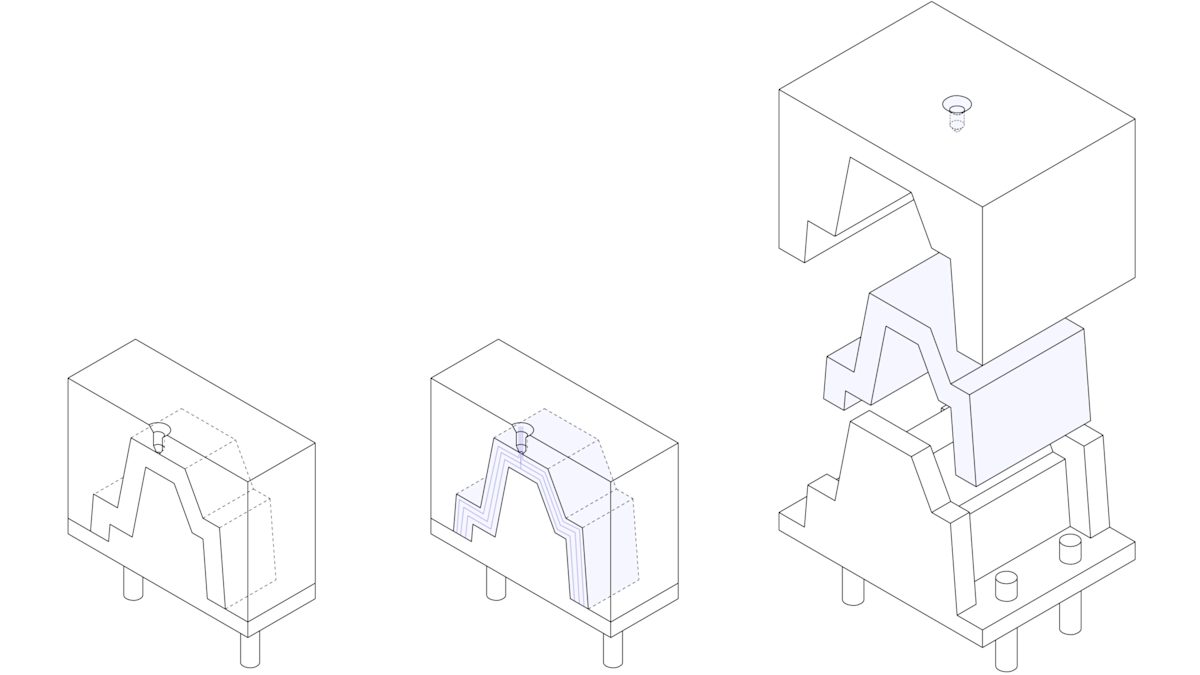

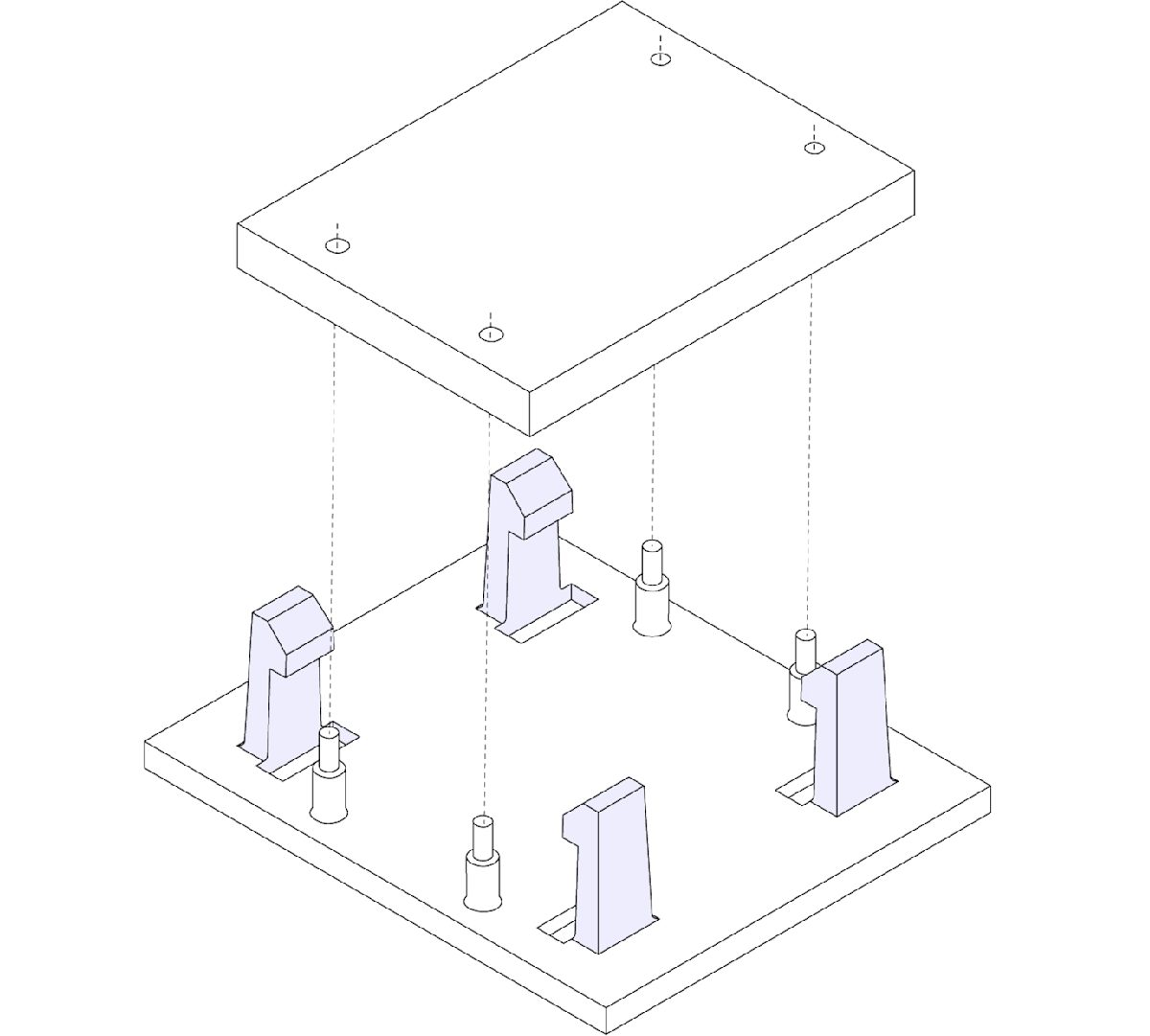

The anatomy of the mold

The simplest mold is the straight-pull mold. It consist of 2 halves: the cavity (the front side) and the core (the back side).

In most cases, straight-pull molds are preferred, as they are simple to design and manufacture, keeping the total cost relatively low. There are some design restrictions though: the part must have a 2.D geometry on each side and no overhangs (i.e. areas that are not supported from below).

If more complex geometries are required, then retractable side-action cores or other inserts are required.

Side-action cores are moving elements that enter the mold from the top or the bottom and are used to manufacture parts with overhangs (for example, a cavity or a hole). Side-actions should be used sparingly though, as the cost increases rapidly.

Interesting fact: About 50% of the typical injection molding cycle is dedicated to cooling and solidification. Minimizing the thickness of a design is key to speed up this step and cuts costs.

The 2 sides of the mold: A side & B side

Injection molded parts have two sides: the A side, which faces the cavity (front half of the mold) and the B side, which faces the core (back half of the mold). These two sides usually serve different purposes:

- The A side usually has better visual appearance and is often called the cosmetic side. The faces on the A side will be smooth or will have a textured according to your design specifications.

- The B side usually contains the hidden (but very important) structural elements of the part (the bosses, ribs, snap-fits and so on). For this reason it is called the functional side. The B side will often have a rougher finish and visible marks from the ejector pins.

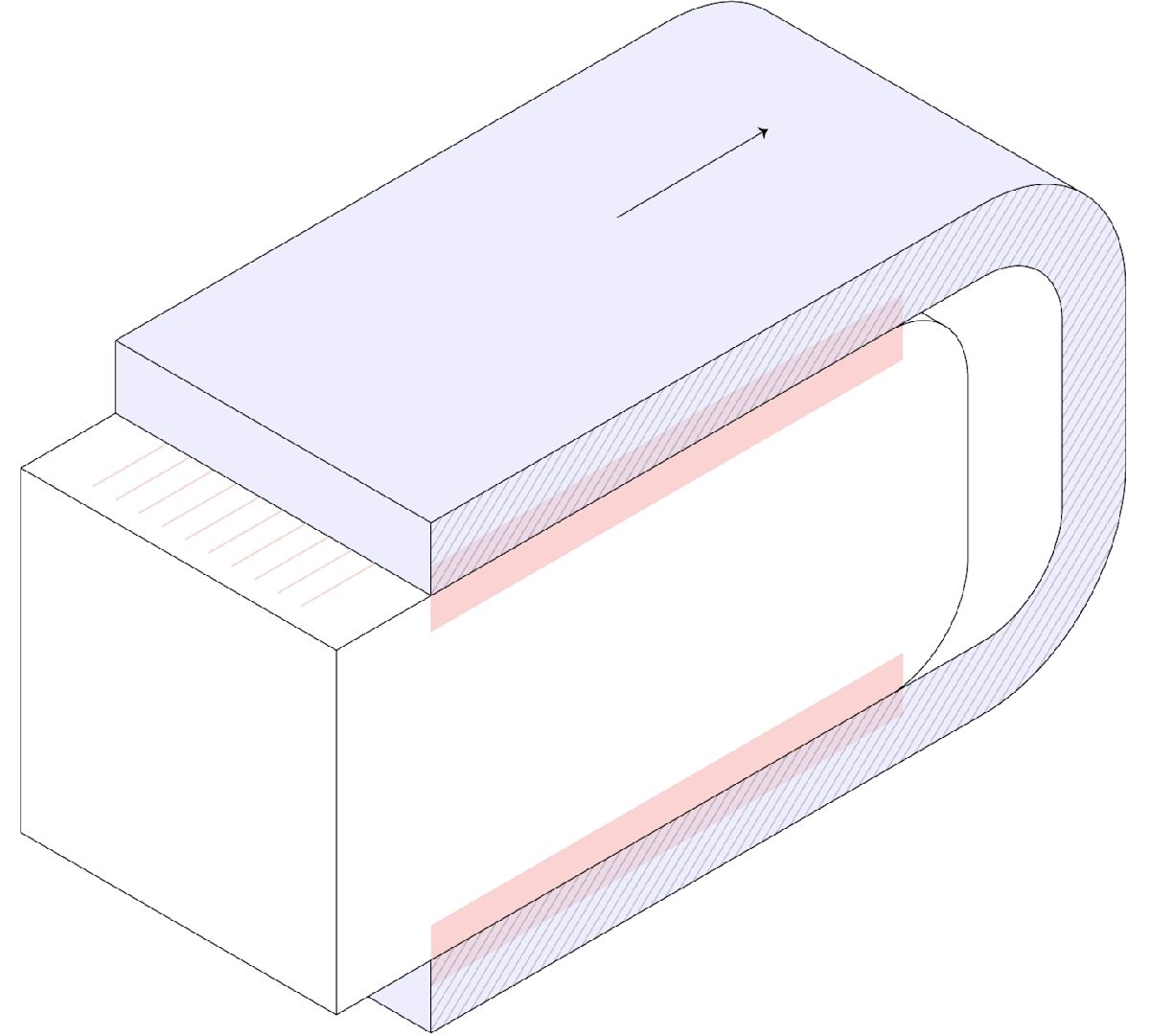

Injecting material into the mold: The runner system

The runner system is the channel that guides the melted plastic into the cavity of the mold. It controls the flow and pressure with which the liquid plastic is injected into the cavity and it is removed after ejection (it snaps off). The runner system usually consists of 3 main sections:

- The sprue is the main channel in which all the melted plastic initially flows through as it enters the mold.

- The runner spreads the melted plastic along the face where the two halves of the mold meet and connects the spur to the gates. There may be one or more runners, guiding the material towards one or multiple parts. The runner system is cut off from the part after ejection. This is the only material waste in injection molding, 15-30% of which can be recycled and reused.

- The gate (is the entry point of the material into the cavity of the mold. Its geometry and location is important, as it determines the flow of the plastic.

Different gates types are suitable for different applications. There are 4 types of gates used in injection molding:

- Edge gates inject material at the parting line of the two halves of the mold and are the most common gate type. The runner system has to be removed manually later, leaving a small imperfection at the injection point.

- Tunnel gates inject material below the parting line. The runner system snaps off as the part is ejected from the mold, eliminating the need for manual removal. This makes this type of gate ideal for very large volumes.

- Post gates inject the material from the backside of the cavity, hiding the small imperfection left from breaking the other gate types. These gates are used for parts that require excellent visual appearance.

- Hot tips are directly connected to the spur and inject plastic from the top side of the part. No material is wasted this way on the runner system making them ideal for large scale production, but a dimple will be visible at the injection point.

The vestige

At the point where the runner system connected with the part, a small imperfection is usually visible, called the vestige.

If the presence of the vestige is not desirable for aesthetic purposes, then in can also be “hidden” in the functional B-side of the part.

The clamping and ejection system

On the far side of an injection molding machine is the clamping system. The clamping system has a dual purpose: it keeps the 2 parts of the mold tightly shut during injection and it pushes the part out of the mold after it opens.

After the part is ejected, it falls onto a conveyor belt or a bucket for storage and the cycle starts over again.

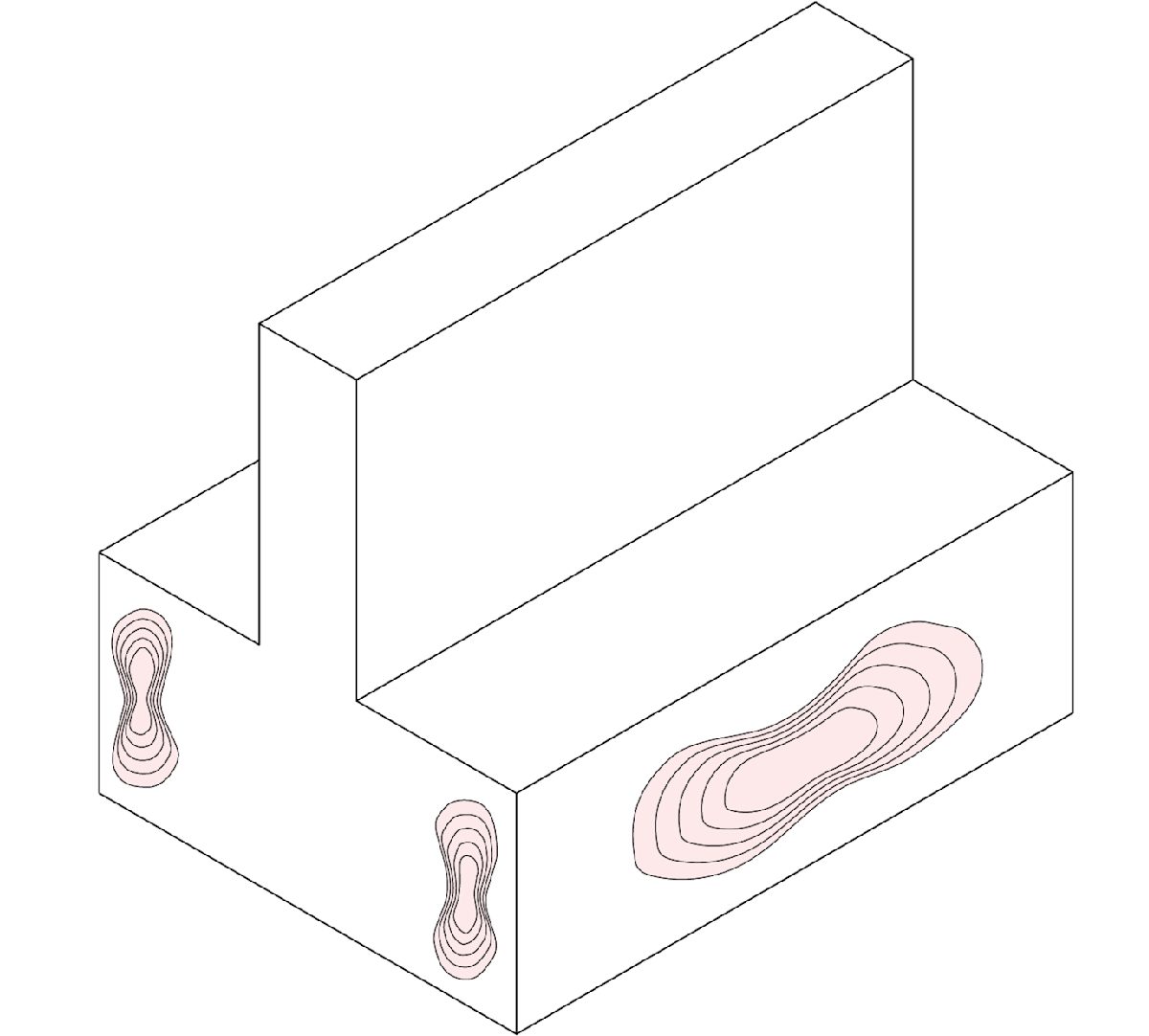

Alignment of the different moving parts of the mold is never perfect though. This causes the creation of 2 common imperfections that are visible on almost every injection molded part:

-

Parting lines which are visible on the side of a part where the 2 halves of the mold meet. They are caused by tiny misalignments and the slightly rounded edges of the mold.

-

Ejector (or witness) marks which are visible on the hidden B-side of the part. They are created because the ejector pins are slightly protruding above or indented below the surface of the mold.

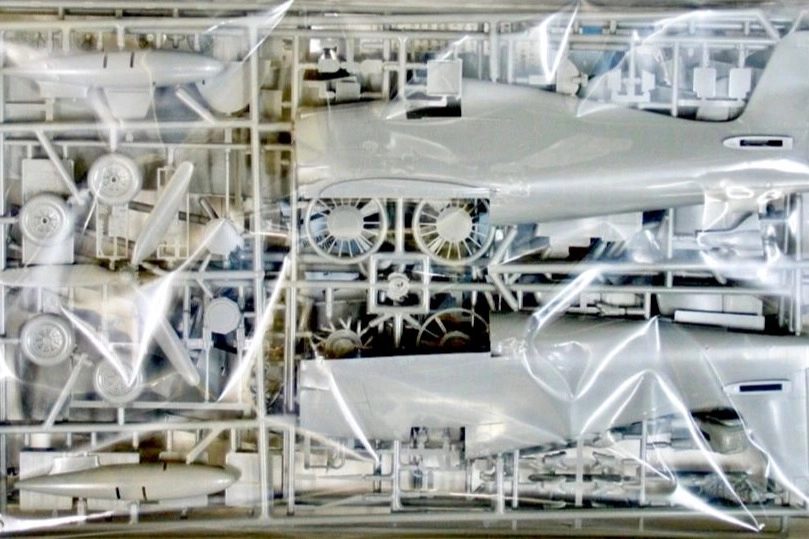

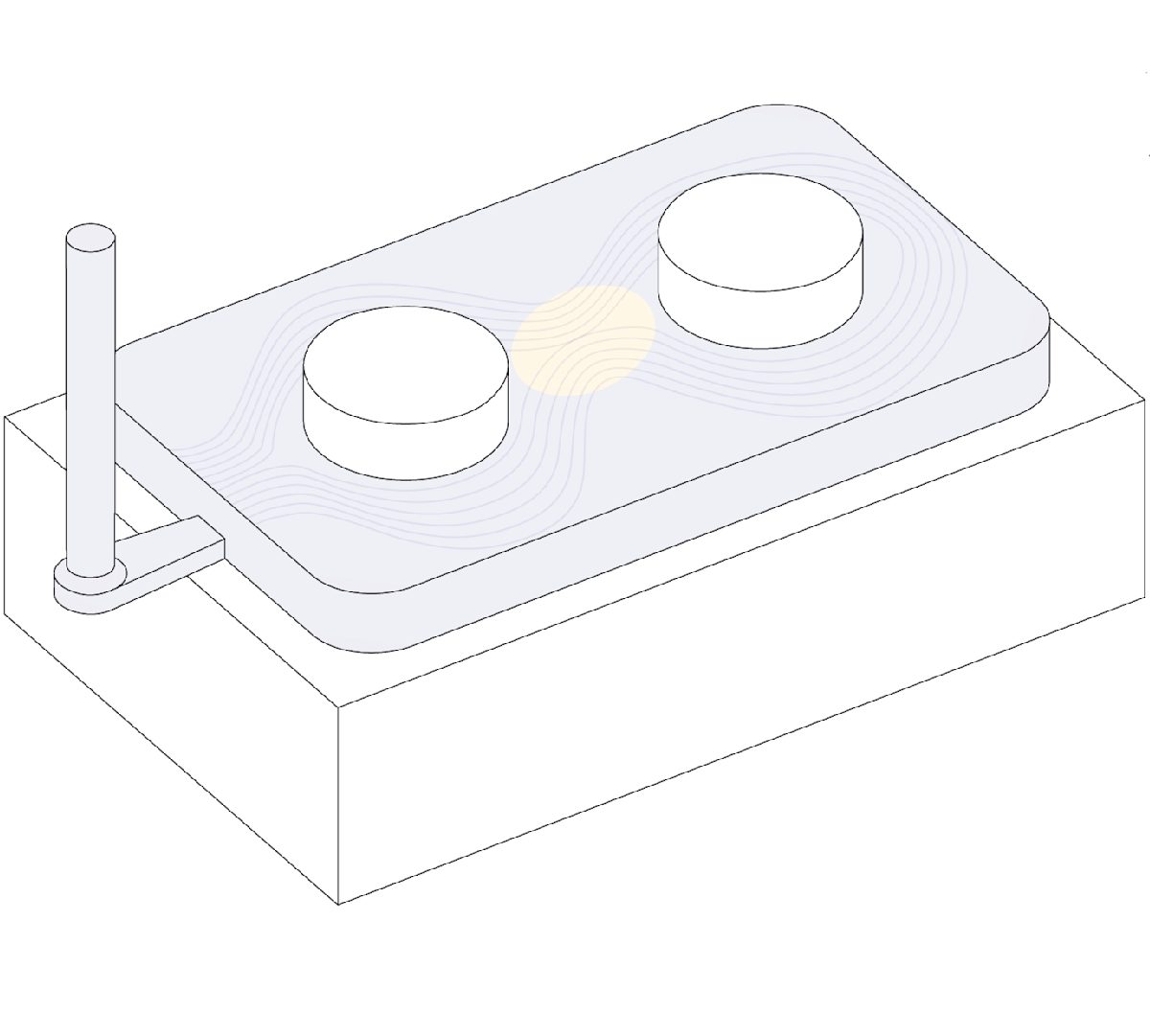

The image below shows the mold used to manufacture both sides of the casing for a remote controller. Quick quiz: try to locate the *core* (A-side), the *cavity* (B-side), the runner system, the ejector pins, the side-action core and the air vents on this mold.

Benefits and limitations of injection molding

Injection molding is an established manufacturing technology with a long history, but it’s constantly being refined and improved with new technological advancements.

Below is a quick rundown of the key advantages and disadvantages of injection molding to help you understand whether it’s the right solution for your application.

Benefits of injection molding

Injection molding is the most cost-competitive technology for manufacturing high volumes of identical plastic parts. Once the mold is created and the machine is set up, additional parts can be manufactured very fast and at a very low cost.

The recommended minimum production volume for injection molding is 500 units. At this point economies of scale start to kick-in and the relatively high initial costs of tooling have a less prominent effect on the unit price.

Almost every thermoplastic material (and some thermosets and silicones) can be injection molded. This gives a very wide range of available materials with diverse physical properties to design with.

Parts produced with injection molding have very good physical properties. Their properties can be tailored by using additives (for example, glass fibres) or by mixing together different pellets (for instance, PC/ABS blends) to achieve the desired level of strength, stiffness or impact resistance.

The typical injection molding cycle lasts 15 to 60 seconds, depending on the size of the part and the complexity of the mold. In comparison, CNC machining or 3D printing might require minutes to hours in order to produce the same geometry. Also, a single mold can accomodate multiple parts, further increasing the production capabillities of this manufacturing process.

This means that hundreds (or even thousands) of identical parts can be produced every single hour.

The injection molding process is highly repeatable and the produced parts are essentially identical. Of course, some wear occurs to the mold over time, but a typical pilot-run aluminum mold will last 5,000 to 10,000 cycles, while full-scale production molds from tool steel can stand 100,000+ cycles.

Typically, injection molding will produce parts with tolerances of ± 0.500 mm (0.020’’). Tighter tolerances down to ± 0.125 mm (0.005’’) are also feasible in certain circumstances. This level of accuracy is enough for most applications and comparable to both CNC machining and 3D printing.

A key strength of injection molding is it can produce finished products that need little to no extra finishing. The surfaces of the mold can be polished to a very high degree to create mirror-like parts. Or they can be bead blasted to create textured surfaces. The SPI standards dictate the level of finishing that can be achieved.

Limitations of injection molding

The main economic restriction of injection molding the the high cost of tooling. Since a custom mold has to be made for each geometry, the start-up costs are very high. These are mainly related to the design and manufacturing of the mold which typically costs between $5,000 and $100,000. For this reason, injection molding is only economically viable for productions larger than 500 units.

After a mold is manufactured, it’s very expensive to modify. Design changes usually require the creation of a new mold from scratch. For this reason, correctly designing a part for injection molding is very important.

In Part 2, we list the most important design considerations to keep in mind while designing for injection molding. It Part 5, we’ll also see how you can mitigate the risk by creating physical prototypes of your parts.

The typical turnaround for injection molding varies between 6-10 weeks. 4-6 weeks to manufacture the mold, plus 2-4 more weeks for production and shipping. If design changes are required (something quite common) the turnaround time increases accordingly.

In comparison, parts made in a desktop 3D printer can be ready for delivery overnight, while industrial 3D printing systems have a typical lead time of 3-5 days. CNC machined parts are typically delivered within 10 days or as fast as 5 days.

Examples of products made with injection molding

If you look around you right now, you’ll see at least a few products that were manufactured with injection molding. You’re probably looking at one right now actually: the casing of the device you are using to read this guide.

To recognize them, look out for these 3 things: a parting line, witness marks on the hidden side and a relatively uniform wall thickness throughout the part.

We’ve collected some examples of products commonly manufacturing with injection molding to help get a better understanding of what can be achieved with this manufacturing process.

Lego bricks

Lego bricks are one of the most recognizable examples of injection molded parts. They’re manufactured using molds, like the one in the picture, which produced 120 million lego bricks (that’s 15 million cycles) before it was taken out of commission.

The material used for Lego bricks is ABS because of its high impact resistance and excellent moldabillity. Every single brick has been designed to perfection, achieving tolerances down to 10 micro meters (or a tenth of a human hair).

This is partly achieved by using the best design practices, which we’ll examine in the next section (uniform wall thickness, draft angles, ribs, embossed text etc.).

Bottle caps

Many plastic packaging products are injection molded. In fact, packaging is the largest market for injection molding.

For example, bottle caps are injection molded from Polypropylene. Polypropylene (PP) has excellent chemical resistance and is suitable to come in contact with food products.

On bottle caps, you can also see all the common unavoidable injection molding imperfections (parting line, ejector marks etc.) and common design features (ribs, stripping undercuts etc.).

Model airplanes

Model airplanes are another common example of injection molded parts. The material used here is mostly Polystyrene (PS), for its low cost and ease of molding.

What’s interesting with model airplane kits is that they come with the runner system still attached. So, you can see the path the melted plastic followed to fill the empty mold.

Car parts

Almost every plastic component in the interior of a car was injection molded. The 3 most common injection molding materials used in the automotive industry are Polypropylene (PP) for non-critical parts, PVC for its good weather resistance and ABS for its high impact strength.

More than half of the plastic parts of a car are made from one of these materials, including the bumpers, the interior body parts and the dashboards.

Consumer electronics

The enclosures of almost every mass-produced consumer electronic device was injection molded. ABS and polystyrene (PS) are prefered here for their excellent impact resistance and good electrical insulation.

Medical devices

Many sterilizable and biocompatible materials are available for injection molding.

Medical grade silicone is one of the more popular materials in the medical industry. Silicone is a thermoset though, so special machinery and process control are required, increasing the cost.

For applications with less strict requirements other materials, like ABS, polypropylene (PP) and Polyethylene (PE), are more common.

Learn more about medical device manufacturing →

Part 2

Design for injection molding

There are several factors that may affect the quality of the final product and the repeatability of the process. To yield the full benefits of the process, the designer must follow certain design guidelines.

In this section, we outline common defects of injection molding and basic and advanced guidelines to follow when designing parts, including recommendations for keeping the costs to a minimum.

Common injection molding defects

Most defects in injection molding are related to either the flow of the melted material or its non-uniform cooling rate during solidification.

Here is a list of defects to keep in mind while designing a part for injection molding. In the next section, we’ll see how you can avoid each of them by following good design practices.

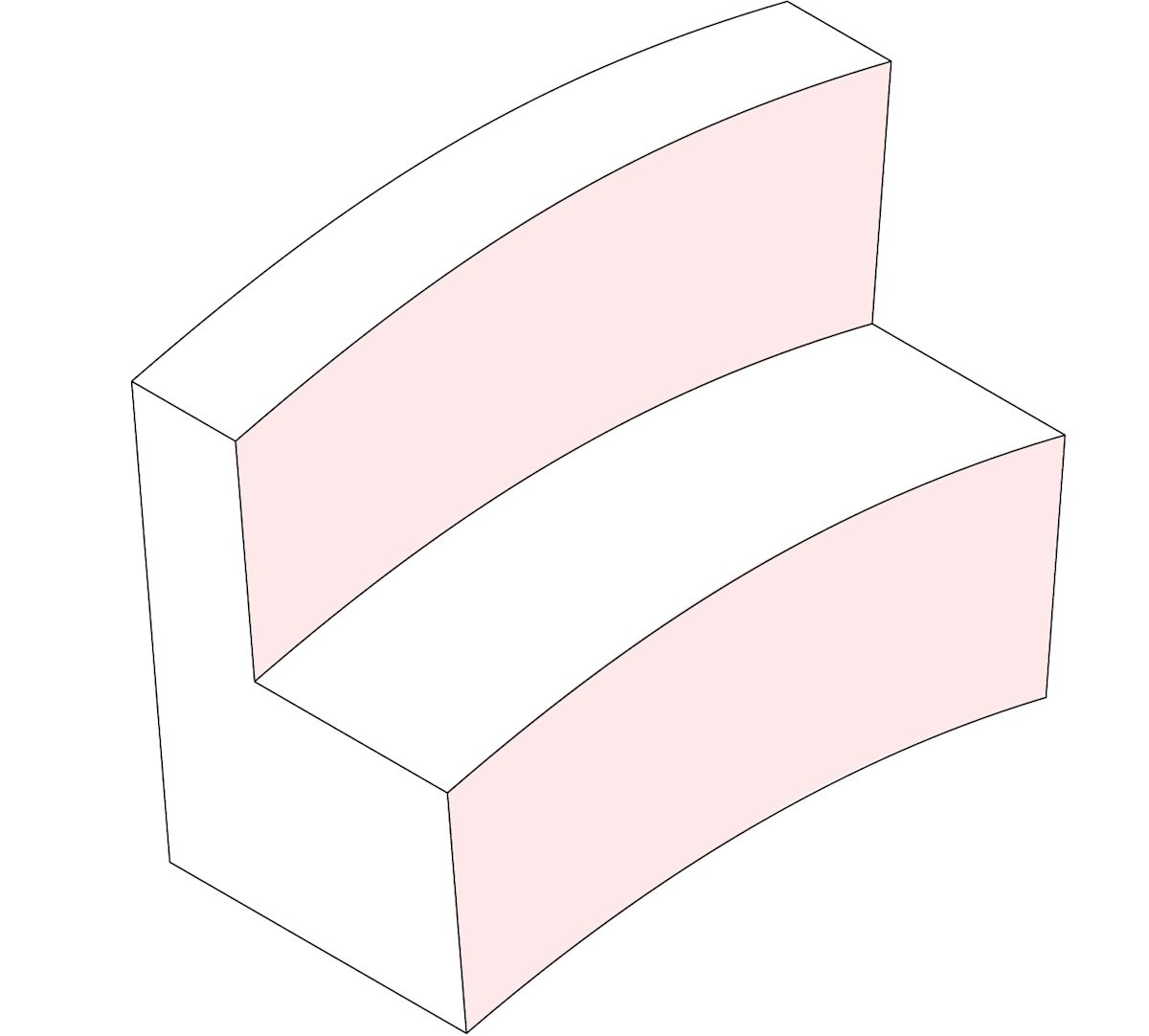

Warping

When certain sections cool (and as a result shrink) faster than others, then the part can permanently bend due to internal stresses.

Parts with non-constant wall thickness are most prone to warping.

Sink marks

When the interior of a part solidifies before its surface, a small recess in an otherwise flat surface may appear, called a sink mark.

Parts with thick walls or poorly designed ribs are most prone to sinking.

Drag marks

As the plastic shrinks, it applies pressure on the mold. During ejection, the walls of the part will slide and scrape against the mold, which can result to drag marks.

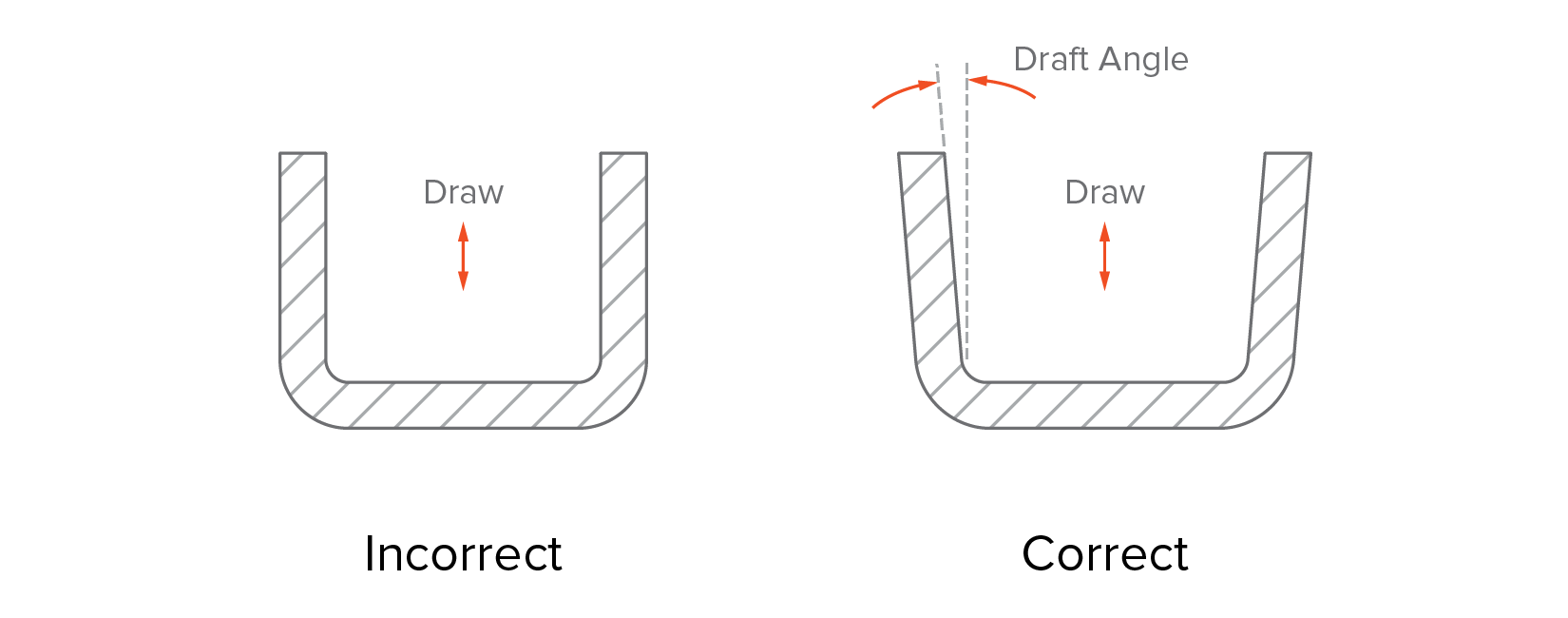

Parts with vertical walls (and no draft angle) are most prone to drag marks.

Knit lines

When 2 flows meet, small hair-like discolorations may develop. These knit lines affect the parts aesthetics, but also they generally decrease the strength of the part.

Parts with abrupt geometry changes or holes are more prone to knit lines.

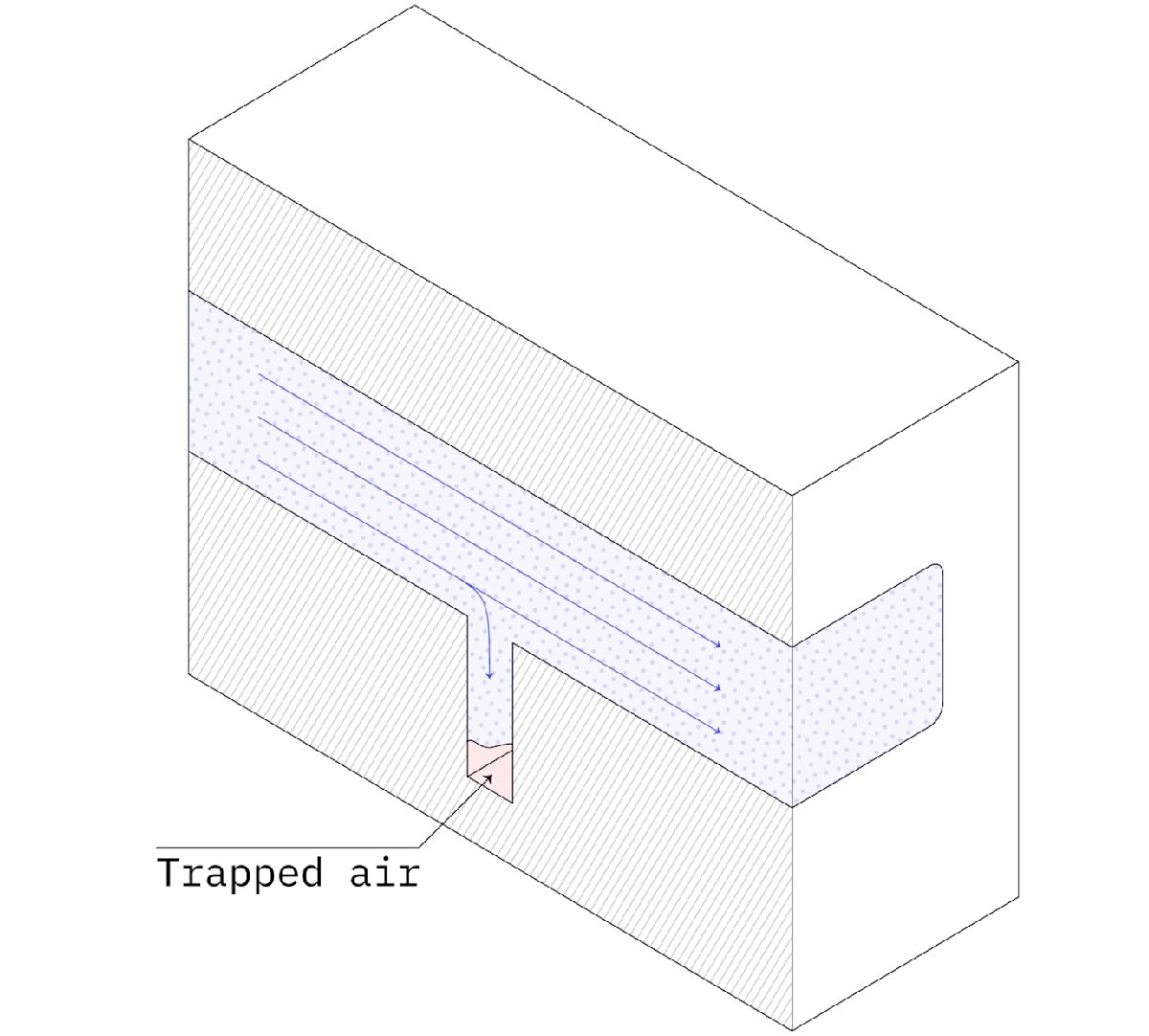

Short shots

Trapped air in the mold can inhibit the flow of the material during injection, resulting in an incomplete part. Good design can improve the flowability of the melted plastic.

Parts with very thin walls or poorly designed ribs are more prone to short shots.

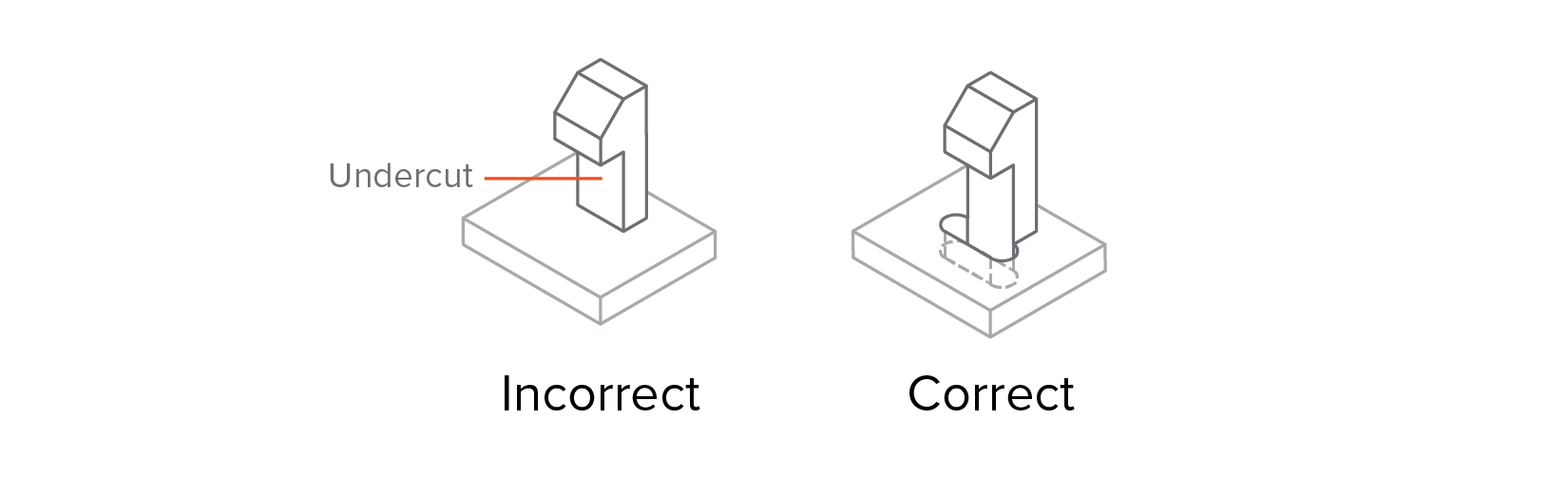

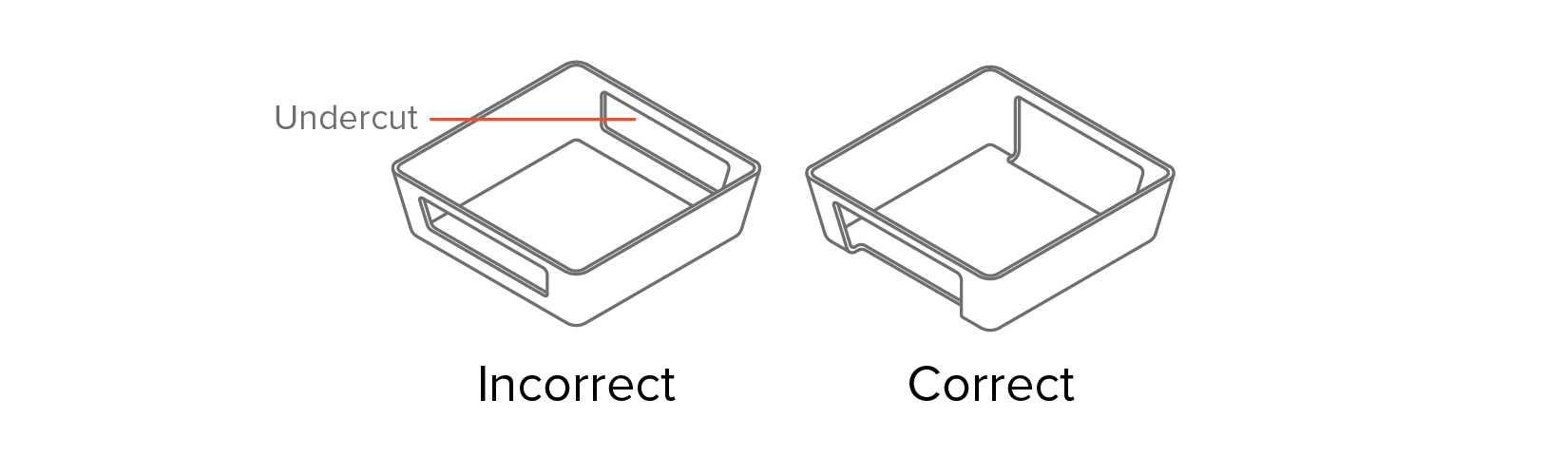

Dealing with undercuts

The simplest mold (the straight-pull mold) consist of 2 halves. Features with undercuts (such as the teeth of a thread or the hook of a snap-fit joint) may not be manufacturable with a straight-pull mold though. This is either because the mold cannot be CNC machined or because the material is in the way of ejecting the part.

Undercuts in injection molding are part features that cannot be manufactured with a simple two-part mold, because material is in the way while the mold opens or during ejection.

The teeth of a thread or the hook of a snap-fit joint are examples of undercuts.

Here some ideas to help you deal with undercuts:

Avoid undercuts using shutoffs

Avoiding undercuts altogether might be the best option. Undercuts always add cost, complexity, and maintenance requirements to the mold. A clever redesign can often eliminate undercuts.

Shut-offs are a useful trick to deal with undercuts on internal regions of the part (for snap-fits) or on the sides of the part (for holes or handles).

Below are some examples of how injection molded parts can be redesigned to avoid undercuts: essentially, material is removed in the area under the undercut, eliminating the issue altogether.

Move the parting line

The simplest way to deal with an undercut is to move the parting line of the mold to intersect with it.

This solution is suitable for many designs with undercuts on an external surface. Don’t forget to adjust the draft angles accordingly.

Use a stripping undercut (bumpoffs)

Stripping undercuts (also known as bumpoffs) can be used when the feature is flexible enough to deform over the mold during ejection. Stripping undercuts are used to manufacture the threads in bottlecaps.

Undercuts can only be used under the following conditions:

- The stripping undercut must be located away from stiffening features, such as corners and ribs.

- The undercut must have a lead angle of 30o to 45o degrees.

- The injection molded part must have space and must be flexible enough to expand and deform.

It is recommended to avoid stripping undercuts in parts made from fiber reinforced plastics. Typically, flexible plastics such as PP, HDPE or Nylon (PA) can tolerate undercuts of up to 5% of their diameter.

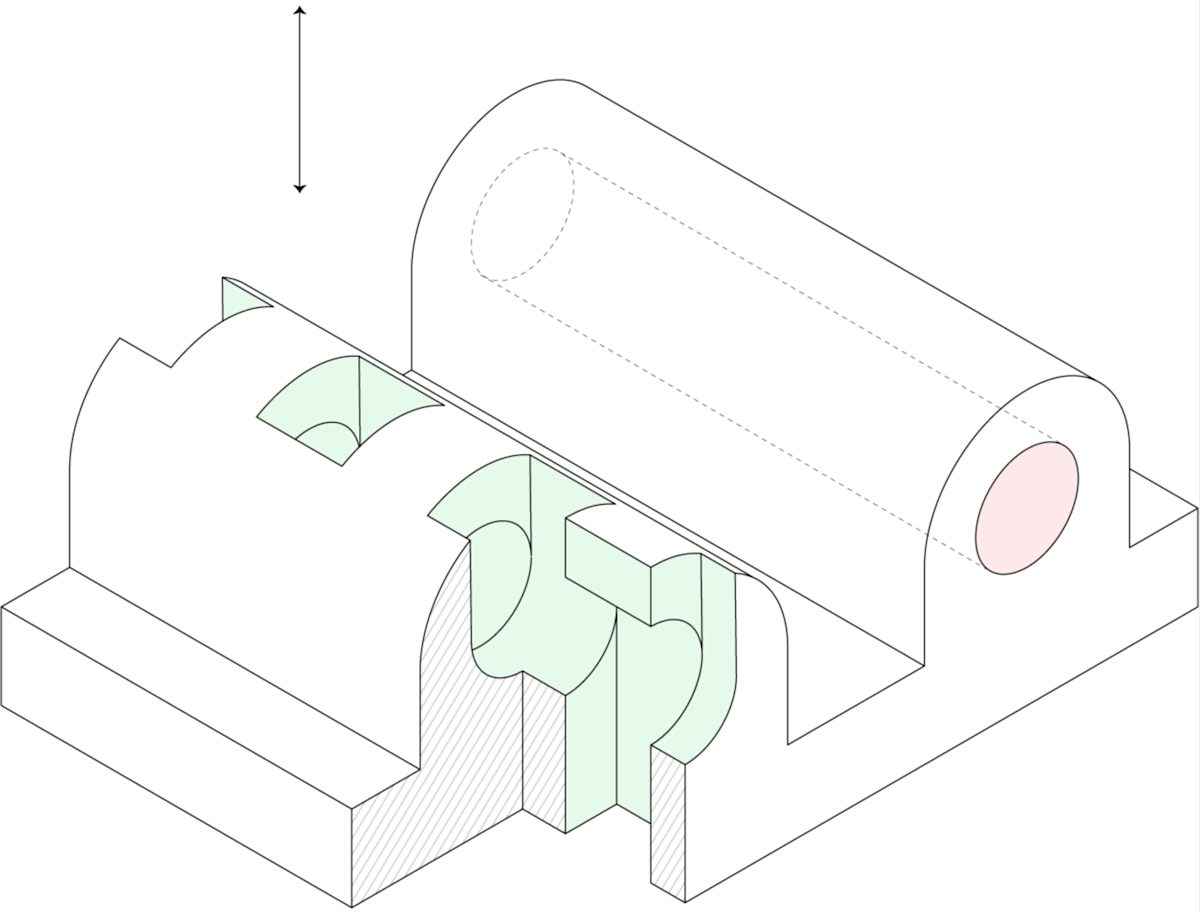

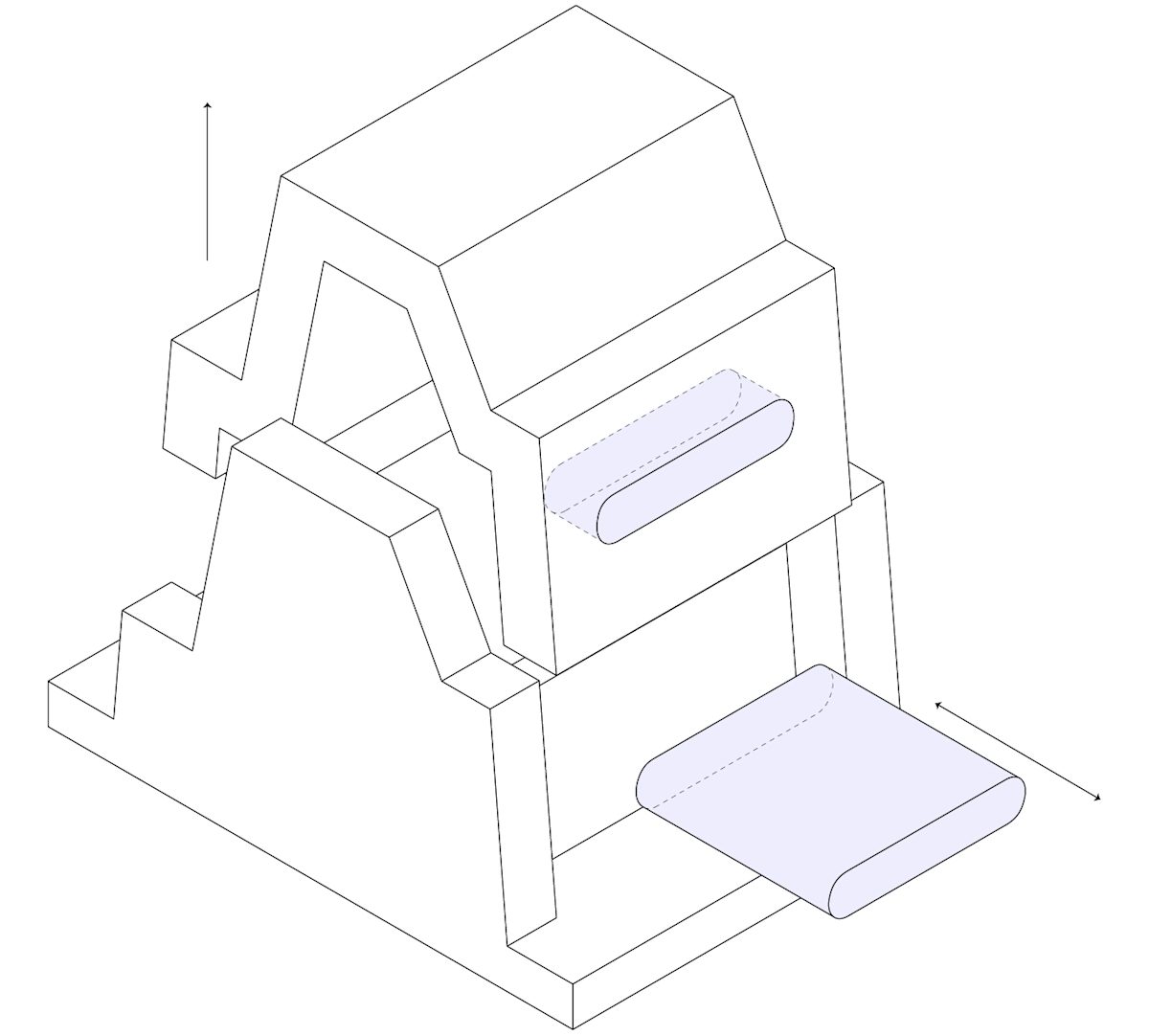

Sliding side-actions and cores

Sliding side-actions and cores are used when it is not possible to redesign the injection molded part to avoid undercuts.

Side-action cores are inserts that slide in as the mold closes and slide out before it opens. Keep in mind that these mechanisms add cost and complexity to the mold.

Follow these guidelines when designing a side actions:

- There needs to be space for the core to move in and out. This means that the feature must be on the other side of the part.

- The side-actions must move perpendicularly. Moving at an angle other than 90° is more complicated, increasing cost and lead times.

- Don’t forget to add draft angles to your design as usual, taking in consideration the movement of the side action core.

Common design features

Learn how to design the most common features encountered in injection molded parts with these practical guidelines. Use them to improve the functionality of your designs, while still complying with the basic design rules.

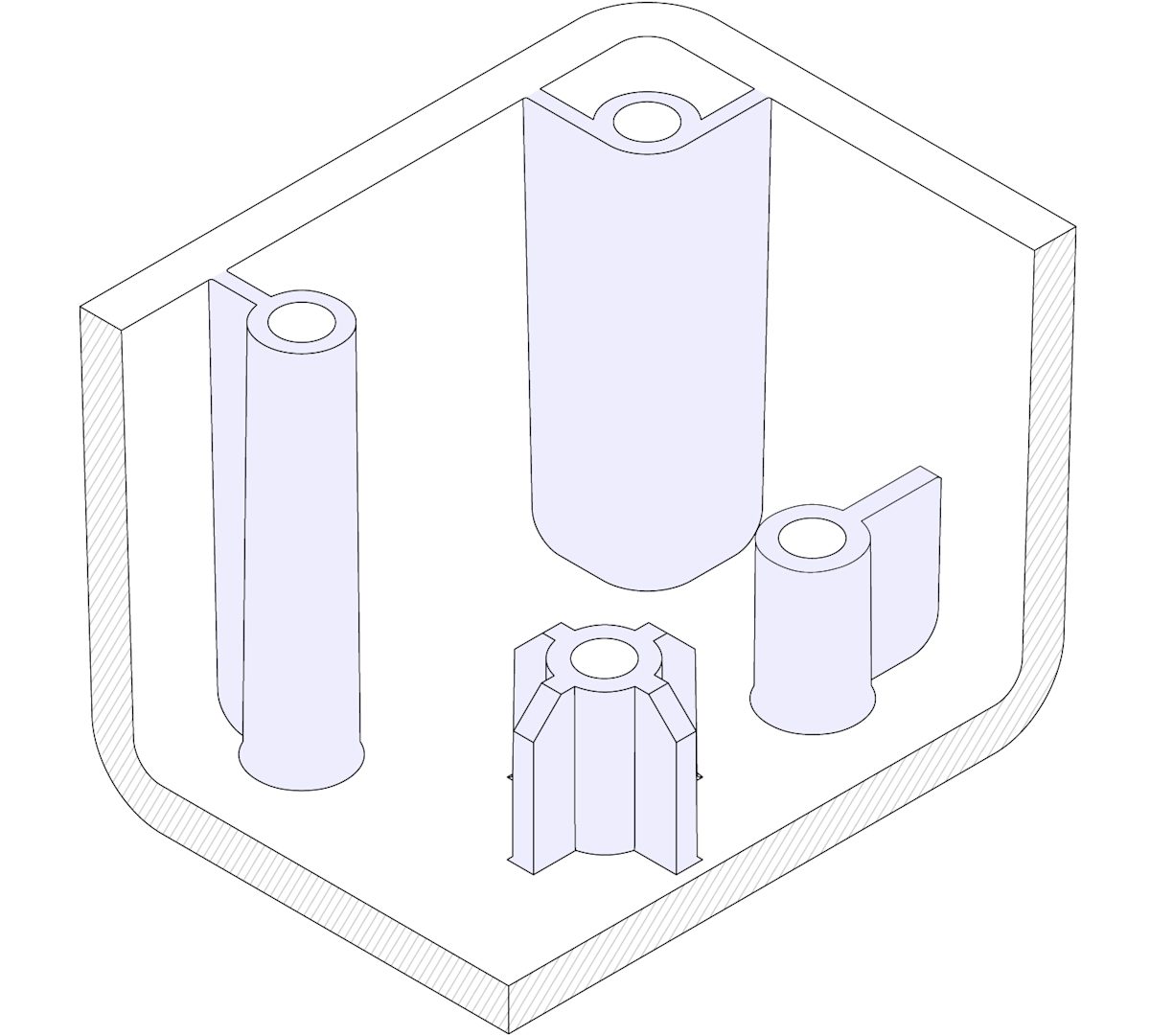

Threaded fasteners (bosses and inserts)

There are 3 ways to add fasteners to an injection molded part: by designing a thread directly on the part, by adding a boss where the screw can be attached, or by including a threaded insert.

Modelling a thread directly on the part is possible, but not recommended, as the teeth of the thread are essentially undercuts, increasing drastically the complexity and cost of the mold (we will more about undercuts in a later section). An example of an injection molded part with a thread are bottle caps.

Bosses

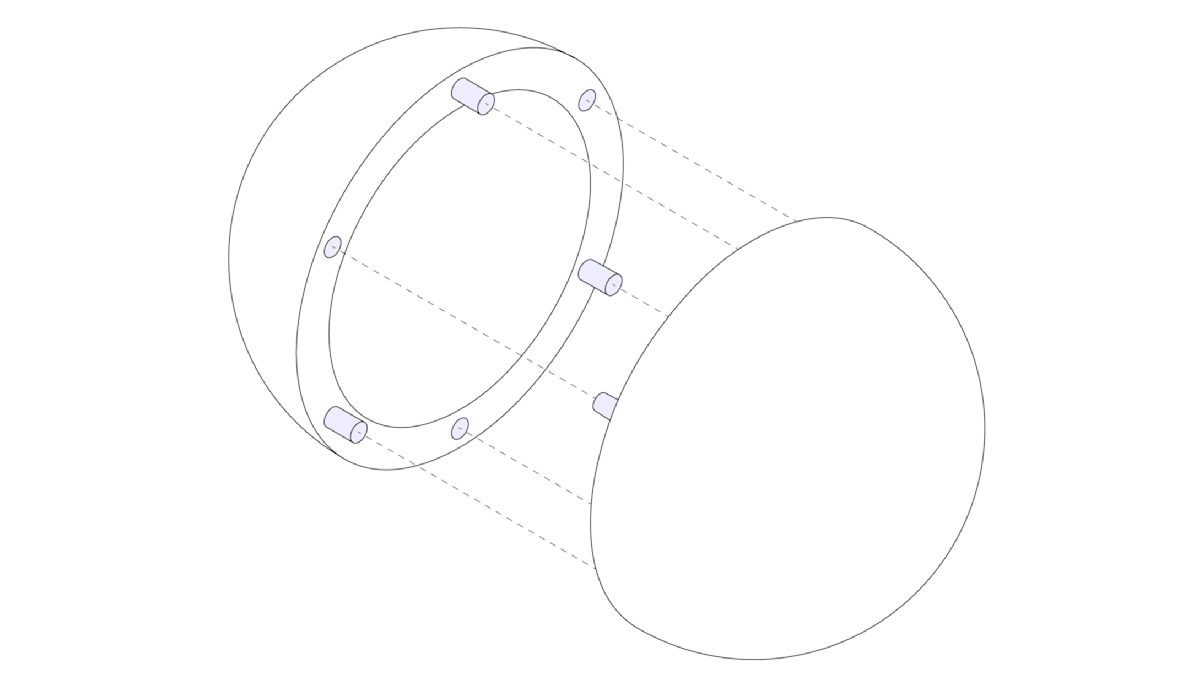

Bosses are very common in Injection Molded parts and are used as points for attachment or assembly. They consist of cylindrical projections with holes designed to receive screws, threaded inserts, or other types of fastening and assembly hardware. A good way to think of a boss is as a rib that closes on itself in a circle.

Bosses are used as points of attachment or fastening (in conjuction with self-tapping screws or threaded inserts).

When bosses are used as __points of fastening__, the outer diameter of the boss should be 2x the nominal diameter of the screw or insert and its inner diameter equal to the diameter of the core of the screw. The hole of the boss should extend to the base-wall level, even if the full depth is not needed for assembly, to maintain a __uniform wall thickness__ throughout the feature. Add a chamfer for easy insertion of the screw or insert.

__For best results:__

Threads

Metal threaded inserts can be added to plastic Injection Molded parts to provide a durable threaded hole for fasteners such as machine screws. The advantage of using inserts is that they allow many cycles of assembly and disassembly.

Inserts are installed in Injection Molded parts through thermal, ultrasonic or in-mold insertion. To design a boss that will receive a threaded insert, use similar guidelines as above, using the diameter of the insert as the guiding dimension.

__For best results:__

Best way to deal with the created undercuts:

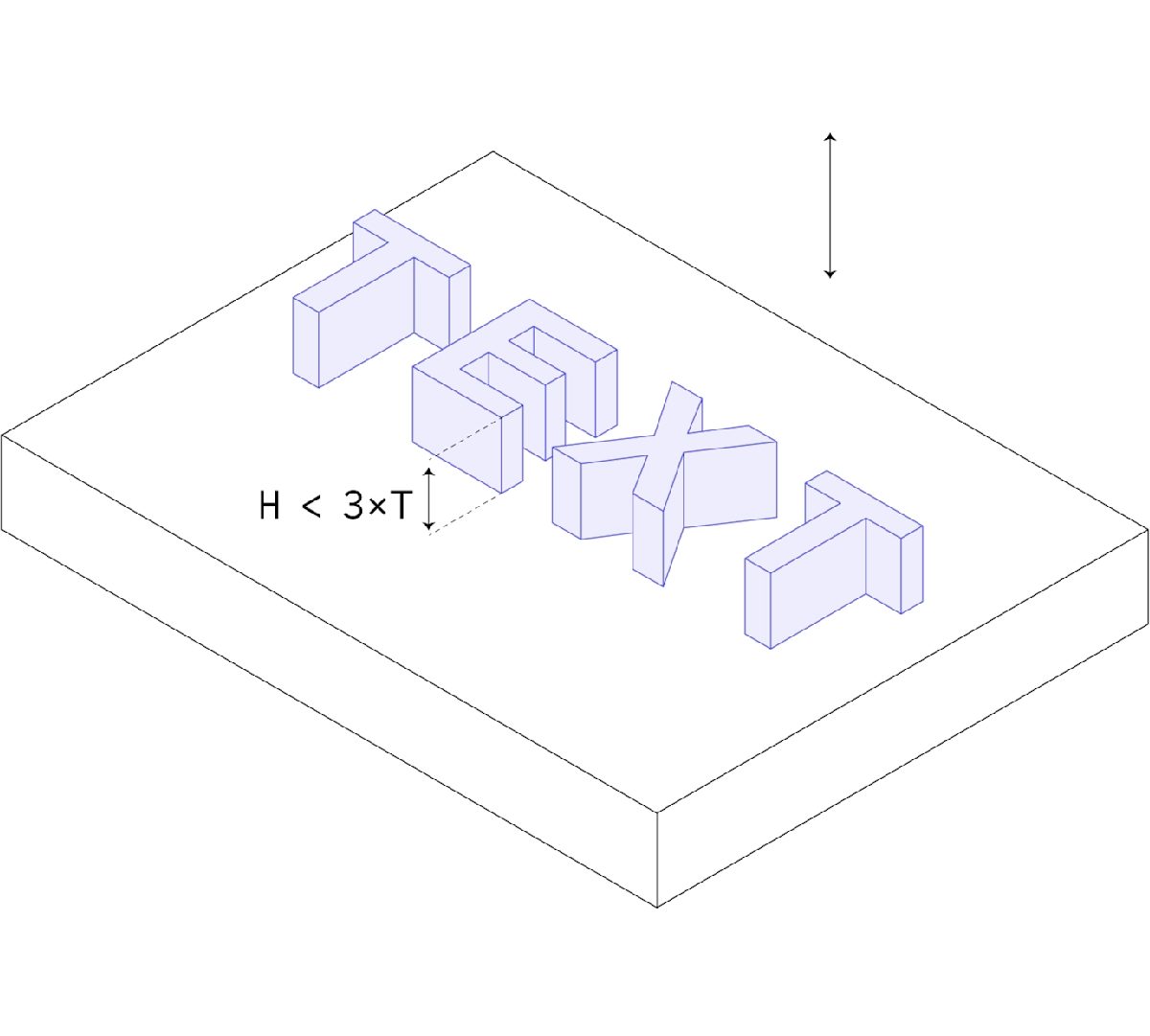

Ribs

When even the maximum recommended wall thickness is not enough to meet the functional requirements of a part, ribs can be used to improve its stiffness.

When designing ribs:

● Use a thickness equal to 0.5 × main wall thickness

● Define a height smaller than 3 × rib thickness

● Use a base fillet with radius greater then ¼ × rib thickness

● Add a draft angle of at least 0.25° - 0.5°

● Add a min. distance between ribs and walls of 4 × rib thickness

Snap-fit joints

Snap-fit joints are a very simple, economical and rapid way of joining two parts without fasteners or tools. A wide range of design possibilities exists for snap-fit joints.

As a rule of thumb, the deflection of a snap-fit joint mainly depends on its length and the permissible force that can be applied on it on its width (since its thickness is more or less defined by the wall thickness of the part). Also, snap-fit joints are another example of undercuts.

In the example above, the most common snap-fit joint design (known as the __cantilever snap-fit joint__) is shown. As with ribs, add a draft angle to your snap-fit joints and use a minimum thickness of 0.5x the wall thickness.

Specific guidelines on designing snap-fit joints is a big subject that goes beyond the scope of this article. For more detailed information, please refer to this article from MIT.

For best results:

Living hinges

Living hinges are thin sections of plastic that connect 2 segments of a part and allow it to flex and bend. Typically these hinges are incorporated in mass-produced containers, such as plastic bottles. A well-designed living hinge can last for up to a million cycles without failure.

The material used to injection mold a living hinge must be flexible. Polypropylene (PP) and Polyethylene (PE) are good choices for consumer application and Nylon (PA) for engineering uses.

A well-designed hinge is shown below. The recommended minimum thickness of the hinge ranges between 0.20 and 0.35 mm, with higher thicknesses resulting in more durable, but stiffer, parts.

{{img}}

*Example of a living hinge (left) and recommended design dimensions for PP or PE (right)*

Before going to full-scale production, prototype your living hinges using

CNC machining or

3D printing to determine the geometry and stiffness that best fits your application. Add generous fillets and design shoulders with a uniform wall thickness as the main body of the part to improve the material flow in the mold and minimize the stresses. Divide hinges longer than 150 mm in two (or more) to improve lifetime.

For detailed guidelines, please refer to this MIT guide.

For best results:

-

Design hinges with a thickness between 0.20 and 0.35 mm

-

Select a flexible material (PP, PE or PA) for parts with living hinges

-

Use shoulders with a thickness equal the thickness of the main wall

-

Add fillets as large as possible

Crush ribs

Crush Ribs are small protruding features that deform to create friction when different components are pushed together, securing their possition.

Crush ribs can be an economical alternative for manufacturing high tolerance holes for tight fits. They are commonly used to house bearings or shafts and other press fit applications.

An example of a part with crush ribs is shown below. Using three crush ribs is recommended to ensure good alignment. The recommended height/radius for each rib is 2 mm. Add a minimum interference of 0.25 mm between the crush rib and the fitted part. Because of the small surface contact with the mold, crush ribs can be designed without a draft angle.

__For best results:__

Lettering and symbols

Text is a very common feature that can be useful for logos, labels, warnings, diagrams and instructions, saving the expense of stick-on or painted labels.

When adding text, choose embossed text over engraved text, as it’s easier to CNC machine on the mold and thus more economical.

Also raising the text 0.5 mm above the part surface will ensure that the letters are easy to read. We recommend selecting a bold, rounded font style with uniform line thickness, with a size of 20 points or larger. Some font examples include: Century Gothic Bold, Arial and Verdana.

For best results:

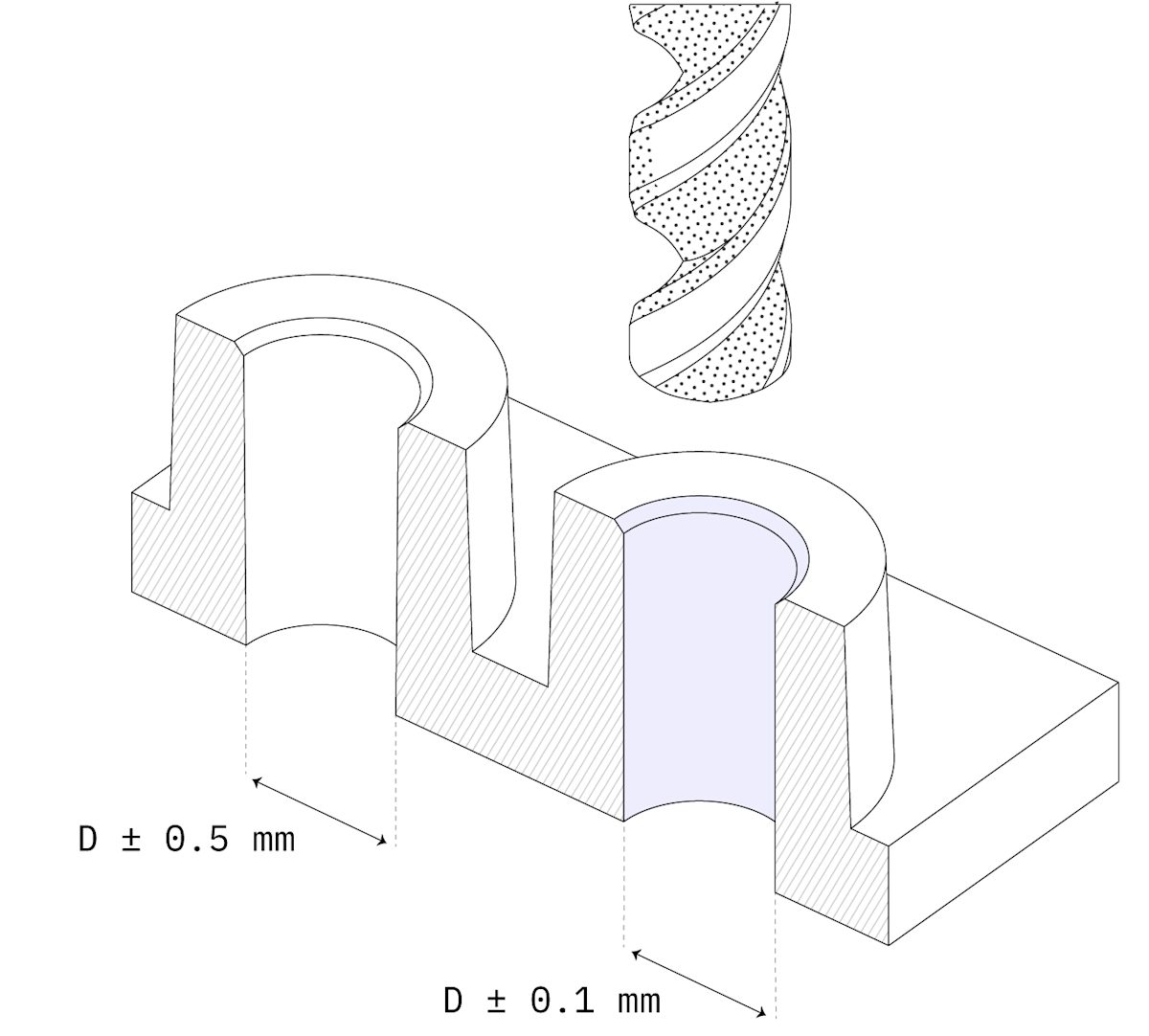

Tolerances

Injection molding typically produces parts with tolerances of ± 0.250 mm (0.010").

Tighter tolerances are feasible in certain circumstances (down to ± 0.125 mm - and even ± 0.025 mm), but they increase the cost drastically.

For small production runs (< 10,000 units), consider using a secondary operation (such as drilling) to improve accuracy. This ensures the correct interference of the part with other components or inserts (for example, when using press fits).

Design rules for injection molding

One of the biggest benefits of injection molding is how easily complex geometries can be formed, allowing a single part to serve multiple functions.

Once the mold is manufactured, these complex parts can be reproduced at a very low cost. But changes to the mold design at later stages of development can be very expensive, so achieving the best results on the first time is essential. Follow the guidelines below to avoid the most common defects in injection molding.

Use a constant wall thickness

Use a uniform wall thickness throughout the part (if possible) and avoid thick sections. This is essential as non-uniform walls can lead to warping or the part as the melted material cools down.

If sections of different thickness are required, make the transition as smooth as possible using a chamfer or fillet. This way the material will flow more evenly inside the cavity, ensuring that the whole mold will be fully filled.

A wall thickness between 1.2 mm and 3 mm is a safe value for most materials. The next table summarises specific __recommended wall thicknesses__ for some of the most common injection molding materials:

| Material | Recommended wall thickness [mm] | Recommended wall thickness [inches] |

|---|---|---|

| Polypropylene (PP) | 0.8 - 3.8 mm | 0.03'' - 0.15'' |

| ABS | 1.2 - 3.5 mm | 0.045'' - 0.14'' |

| Polyethylene (PE) | 0.8 - 3.0 mm | 0.03'' - 0.12'' |

| Polystyrene (PS) | 1.0 - 4.0 mm | 0.04'' - 0.155'' |

| Polyurethane (PUR) | 2.0 - 20.0 mm | 0.08'' - 0.785'' |

| Nylon (PA 6) | 0.8 - 3.0 mm | 0.03'' - 0.12'' |

| Polycarbonate (PC) | 1.0 - 4.0 mm | 0.04'' - 0.16'' |

| PC/ABS | 1.2 - 3.5 mm | 0.045'' - 0.14'' |

| POM (Delrin) | 0.8 - 3.0 mm | 0.03'' - 0.12'' |

| PEEK | 1.0 - 3.0 mm | 0.04'' - 0.12'' |

| Silicone | 1.0 - 10.0 mm | 0.04'' - 0.40'' |

For best results:

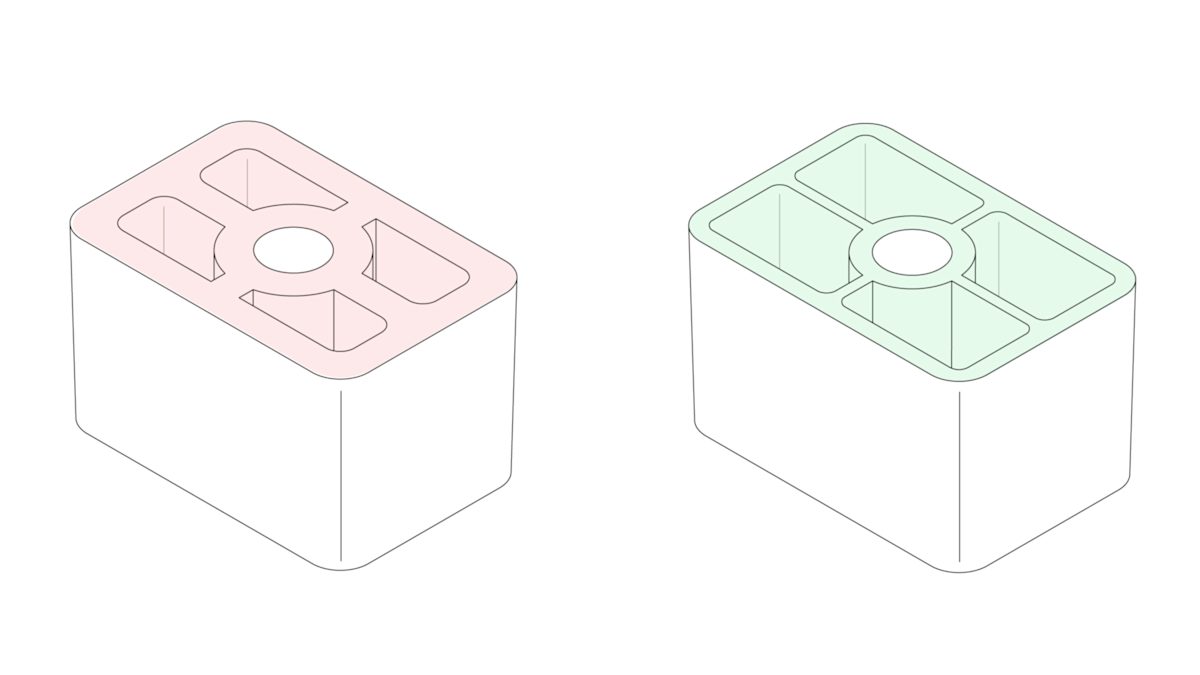

Hollow out thick sections

Thick sections can lead to various defects, including warping and sinking. Limiting the maximum thickness of any section of your design to the recommended values by making them hollow is essential.

To improve the strength of hollow section, use ribs to design structures of equal strength and stiffness but reduced wall thickness. A well-designed part with hollow sections is shown below:

Ribs can also be used to improve the stiffness of __horizontal sections__ without increasing their thickness. Remember though that the wall thickness limitations still apply. Exceeding the recommended rib thickness (see below) can result in sink marks.

For best results:

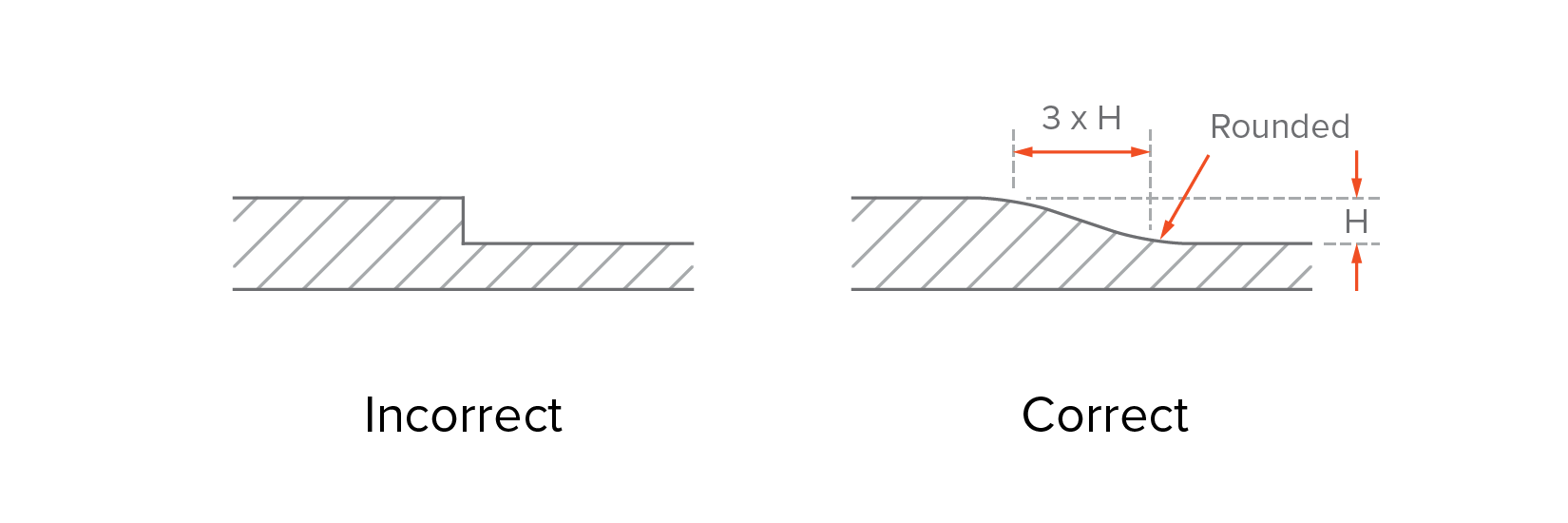

Add smooth transitions

Recommended: 3 × wall thickness difference

Sometimes sections with different wall thicknesses cannot be avoided. In these cases, use a chamfer or fillet to make the transition as smooth as possible.

Similarly, the base of vertical features (like ribs, bosses, snap-fits) must also always be rounded.

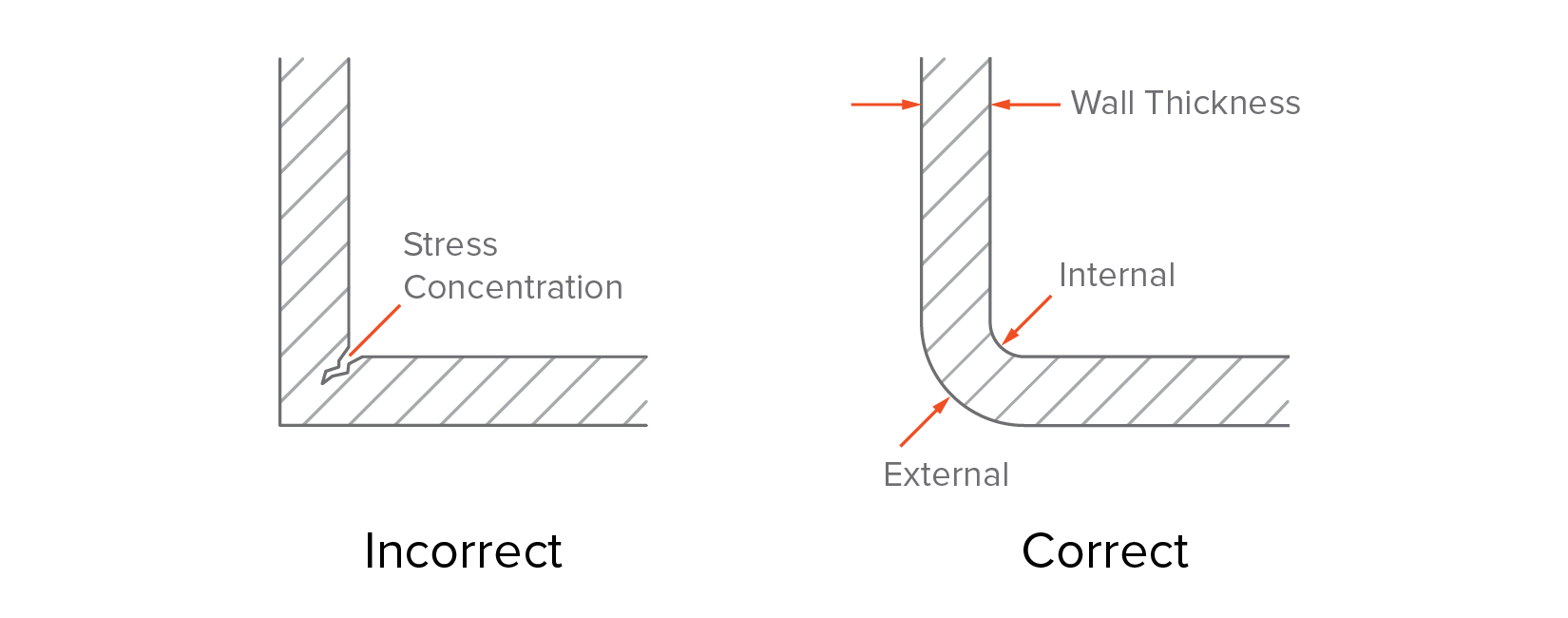

Round all edges

The uniform wall thickness limitation also applies to edges and corners: the transition must be as smooth as possible to ensure good material flow.

For interior edges, use a radius of at least 0.5 x the wall thickness. For exterior edges, add a radius equal to the interior radius plus the wall thickness. This way you ensure that the thickness of the walls is constant everywhere (even at the corners).

Adding to this, sharp corners result in stress concentrations which can result in weaker parts.

For best results:

Add draft angles

To make the ejection of the part from the mold easier, a draft angle must be added to all vertical walls. Walls without a draft angle will have drag marks on their surface, due to the high friction with the mold during ejection.

A minimum draft angle of 2° is recommended. Larger draft angles (up to 5o °) should be used on taller features.

Learn more about the importance of draft angles in this article →

A good rule of thumb is to increase the draft angle by one degree for every 25 mm. For example, add a draft angle of 3o degrees to a feature that is 75 mm tall. Larger draft angle should be used if the part has a textured surface finish. As a rule of thumb, add 1o to 2o extra degrees to the results of the above calculations.

Remember that draft angles are also necessary for ribs. Be aware though that adding an angle will reduce the thickness of the top of the rib, so make sure that your design complies with the recommended minimum wall thickness.

__For best results:__

Part 3

Injection molding materials

Injection molding is compatible with a wide range of plastics. In this section, you’ll learn more about the key characteristics of the most popular materials. We’ll also discuss the standard surface finishes that can be applied to injection molded parts.

Materials used for injection molding

All thermoplastics can be injection molded. Some thermosets and liquid silicones are also compatible with the injection molding process.

They can be also reinforced with fibers, rubber particles, minerals or flame retardant agents to modify their physical properties. For example fiberglass can be mixed with the pellets at ratios of 10%, 15% or 30% resulting in parts with higher stiffness.

Polypropylene (PP)

The most common Injection molding plastic. Excellent chemical resistance. Food-safe grades available. Not suitable for mechanical applications.

ABS

Common thermoplastic with high impact resistance, low-cost & low density. Vulnerable to solvents.

Polyethylene (PE)

Lightweight thermoplastic with good impact strength & weather resistance. Suitable for outdoor applications.

Polystyrene (PS)

The Injection molding plastic with the lowest cost. Food-safe grades available. Not suitable for mechanical applications.

Polyurethane (PU)

Thermoplastic with high impact strength and good mechanical properties & hardness. Suitable for molding parts with thick walls.

Nylon (PA 6)

Engineering thermoplastic with excellent mechanical properties and high chemical & abrasion resistance. Susceptible to moisture.

Polycarbonate (PC)

The plastic with the highest impact strength. High thermal resistance, weather resistance & toughness. Can be colored or transparent.

PC/ABS

Blend of two thermoplastics resulting in high impact strength, excellent thermal stability, and high stiffness. Vulnerable to solvents.

POM (Acetal/Delrin)

Engineering thermoplastic with high strength, stiffness & moisture resistance and self-lubricating properties. Relatively prone to warping.

PEEK

High-performance engineering thermoplastic with excellent strength and thermal & chemical resistance. Used to replace metal parts.

Silicone rubber

Thermoset with excellent heat & chemical resistance and customizable shore hardness. Food-safe and medical grade available.

An additive that is commonly used to improve the stiffness of the injection molded parts is fiberglass. The glass fibers can be mixed with the pellets at ratios of 10%, 15% or 30%, resulting in different mechanical properties.

Colorant can be added to the mixture (at a ratio of about 3%) to create a great variety of colored parts. Standard colors include red, green, yellow, blue, black and white and they can be mixed to create different shades.

Surface finishes and SPI standards

Surface finishes can be used to give an injection molded part a certain look or feel. Besides cosmetic purposes surface finishes can also serve technical needs. For example, the average surface roughness (Ra) can dramatically influence the lifetime of sliding parts such as plain bearings.

Injection molded parts are not usually post-processed, but the mold itself can be finished to various degrees.

Keep in mind that rough surfaces increase the friction between the part and the mold during ejection, therefore a larger draft angle is required.

The Society of Plastics Industry (SPI) explains several standard finishing procedures that result in different part surface finishes.

| Finish | Description | SPI standards* | Applications |

|---|---|---|---|

| Glossy finish | The mold is first smoothed and then polished with a diamond buff, resulting in a mirror-like finish. |

A-1 A-2 A-3 |

Suitable for parts that require the smoothest surface finish for cosmetic or functional purposes (Ra less than 0.10 μm). The A-1 finish is suitable for parts with mirror-like finish and lenses. |

| Semi-gloss finish | The mold is smoothed with fine grit sandpaper, resulting in a fine surface finish. |

B-1 B-2 B-3 |

Suitable for parts that require a good visual appearance, but not a high glossy look. |

| Matte finish | The mold is smoothed using fine stone powder, removing all machining marks. |

C-1 C-2 C-3 |

Suitable for parts with low visual appearance requirements, but machining marks are not acceptable. |

| Textured finish | The mold is first smoothed with fine stone powder and then sandblasted, resulting in a textured surface. |

D-1 D-2 D-3 |

Suitable for parts that require a satin or dull textured surface finish. |

| As-machined finish | The mold is finished to the machinist's discretion. Tool marks will be visible. | - | Suitable for non-cosmetic parts, such industrial or hidden components. |

When selecting a glossy surface finish, remember these useful tips:

- A high glossy mold finish is not equivalent to a high glossy finished product. It is significantly subject to other factors such as plastic resin used, molding condition and mold design. For example, ABS will produce parts with a higher glossy surface finish than PP. To find the recommended material and surface finish combination visit the appendix.

- Finer surface finishes require a higher grade material for the mold. To achieve a very fine polish, tool steels with the highest hardness are required. This has an impact on the overall cost (material cost, machining time and post-processing time).

Part 4

Cost reduction tips

Learn more about the main cost drivers in injection molding and actionable design tips that will help you reduce the costs of your project.

Cost drivers in injection molding

The biggest costs in injection molding are:

- Tooling costs determined by the total cost of designing and machining the mold

- Material costs determined by the volume of the material used and its price per kilogram

- Production costs determined by the total time the Injection molding machine is used

Tooling costs are constant (starting at $3,000 and up to $5,000). This cost is independent of the total number of manufactured parts, while the material and production costs are dependent on the production volume.

For smaller productions (1,000 to 10,000 units), the cost of tooling has the greatest impact on the overall cost (approximately 50-70%). So, it’s worthwhile altering your design accordingly to simplify the process of manufacturing of the mold (and its cost).

For larger volumes to full-scale production (10,000 to 100,000+ units), the contribution of the tooling costs to the overall cost is overshadowed by the material and production costs. So, your main design efforts should focus on minimizing both the volume part and the time of the molding cycle.

Here we collected some tips to help you minimize the cost of your Injection molded project.

Tip #1: Stick to the straight-pull mold

Side-action cores and the other in-mold mechanisms can increase the cost of tooling by 15% to 30%. This translates to a minimum additional cost for tooling of approximately $1,000 to $1,500.

In a previous section, we examined ways to deal with undercuts. To keep your production on-budget, avoid using side-action cores and other mechanisms unless absolutely necessary.

Tip #2: Redesign the injection molded part to avoid undercuts

Undercuts always add cost and complexity, as well as maintenance to the mold. A clever redesign can often eliminate undercuts.

Tip #3: Make the injection molded part smaller

Smaller parts can be molded faster resulting in a higher production output, making the cost per part lower. Smaller parts also result in lower material costs and reduce the price of the mold.

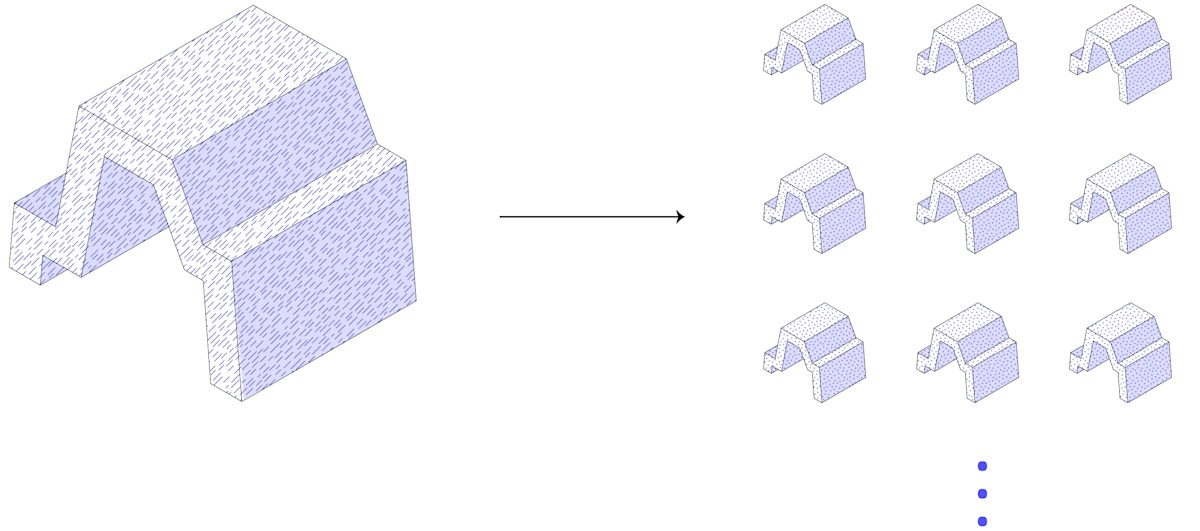

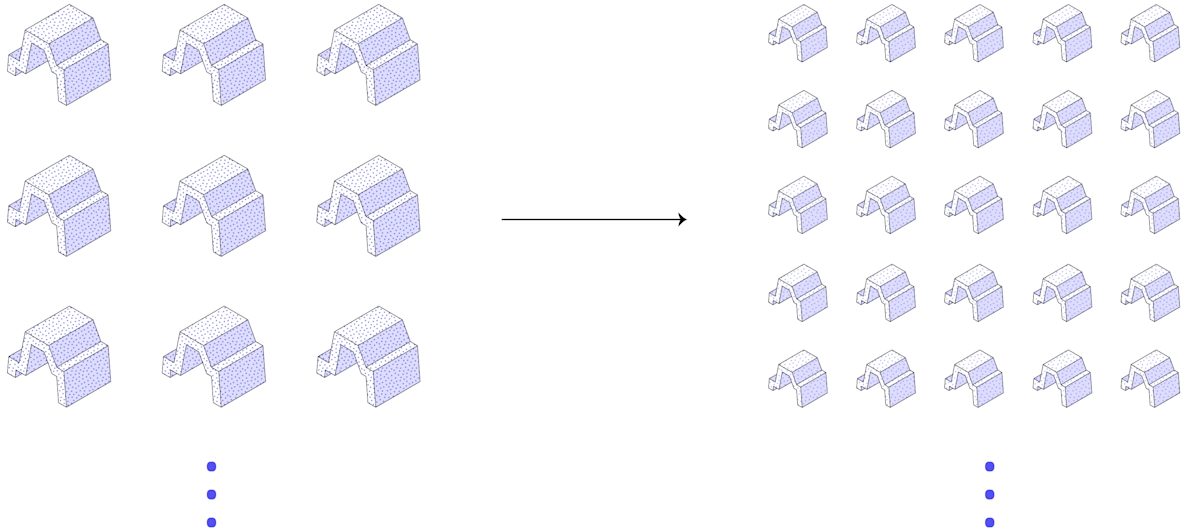

Tip #4: Fit multiple parts in one mold

As we saw in a previous section, fitting multiple parts in the same mold is common practice. Usually, 6 to 8 small identical parts can fit in the same mold, essentially reducing the total production time by about 80%.

Parts with different geometries can also fit in the same mold (remember, the model airplane example). This is a great solution for reducing the overall cost of assembly.

Here’s an advanced technique:

In some cases, the main body of 2 parts of an assembly is the same. With some creative design, you can create interlocks points or hinges at symmetrical locations, essentially mirroring the part. This way the same mold can be used to manufacture both halves, cutting the tooling costs in half.

Tip #5: Avoid small details

To manufacture a mold with small details require longer machining and finishing times. Text is an example of this and might even require specialized machining techniques such as electrical discharge machining (EDM) resulting in higher costs.

Tip #6: Use lower grade finishes

Finishes are usually applied to the mold by hand, which can be an expensive process, especially for high-grade finishes. If your part is not for cosmetic use, don’t apply a costly high-grade finish.

Tip #7: Minimize the part volume by reducing wall thickness

Reducing the wall thickness of your part is the best way to minimize the part volume. Not only does it mean less material is used, but also the injection molding cycle is greatly accelerated.

For example, reducing the wall thickness from 3 mm to 2 mm can reduce the cycle time by 50% to 75%.

Thinner walls mean that the mold can be filled quicker. More importantly, parts thinner parts cool and solidify much faster. Remember that about half the injection molding cycle is spent on the solidification of the part while the machine is kept idle.

Care must be taken through to not overly reduce the stiffness of the part which would downgrade its mechanical performance. Ribs in key locations can be used to increase stiffness.

Tip #8: Consider secondary operations

For lower volume productions (less than 1000 parts), it may be more cost effective to use a secondary operation to complete your injection molded parts. For example, you could drill a hole after molding rather than using an expensive mold with side-action cores.

Part 5

Start Injection molding

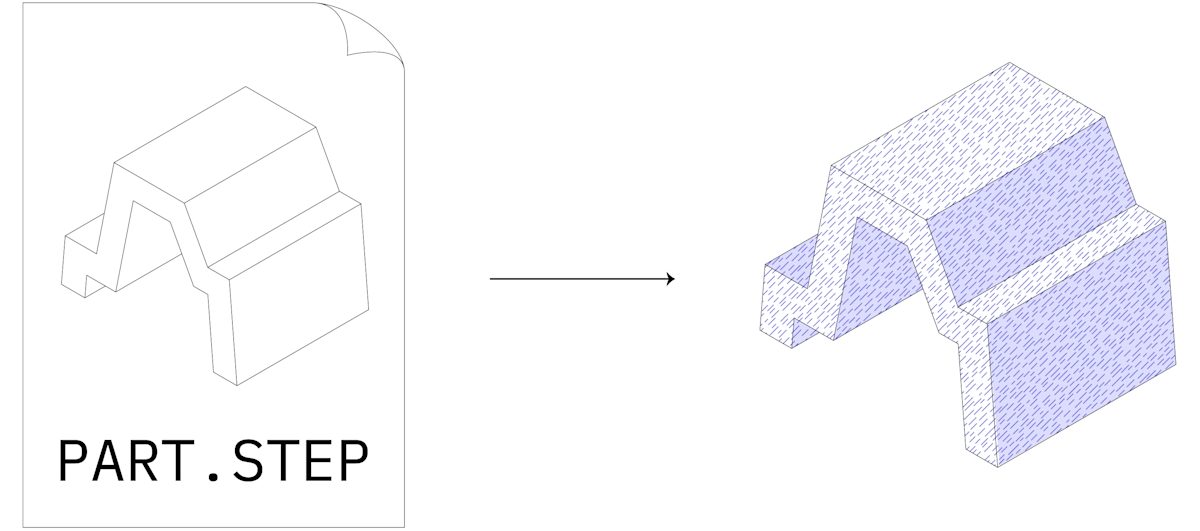

Once your design ready and optimized for injection molding, what’s next? In this section we’ll take you through the steps needed to start manufacturing with injection molding.

Step 1: Start small and prototype fast

Before you commit to any expensive injection molding tooling, first create and test a functional prototype of your design.

This step is essential for launching a successful product. This way design errors can be identified early, while the cost of change is still low.

There are 3 solutions for prototyping:

- 3D printing (with SLS, SLA or Material Jetting)

- CNC machining in plastic

- Low-run injection molding with 3D printed molds These processes can create realistic prototypes for form and function that closely resemble the appearance of the final injection molding product.

Use the information below as a quick comparison guide to decide which solution is best for your application.

Prototyping with 3D printing

Min. quantity: 1 part

Typical cost: $20 - $100 per part

Lead time: 2 - 5 days

Learn more about this process →

Prototyping with CNC machining

Min. quantity: 1 part

Typical cost: $100 - $500 per part

Lead time: 5 - 10 days

Learn more about this process →

Prototyping with low-run injection molding

Min. quantity: 10 - 100 parts

Typical cost: $1000 - $4000 total

Lead time: 5 - 10 days

Learn more about this process →

Step 2 : Make a “pilot run” (500 - 10,000 parts)

With the design finalized, it time to get started with Injection molding with a small pilot run.

The minimum order volume for injection molding is 500 units. For these quantities, the molds are usually CNC machined from aluminum. Aluminum molds are relatively easy to manufacture and low in cost (starting at about $3,000 to $5,000) but can withstand up to 5,000 - 10,000 injection cycles.

At this stage, the typical cost per part varies between $1 and $5, depending on the geometry of your design and the selected material. The typical lead time for such orders is 6-8 weeks.

Don’t get confused by the term “pilot run”. If you only require a few thousand parts, then this would be your final production step.

The parts manufactured with “pilot” aluminum molds have physical properties and accuracy identical to parts manufactured with “full-scale production” tool steel molds.

Step 3 : Scale up production (100,000+ parts)

When producing parts massive quantities of identical parts (from 10,000 to 100,000+ units) then special Injection molding tooling is required.

For these volumes, the molds are CNC machined from tool steel and can withstand millions of Injection molding cycles. They are also equipped with advanced features to maximize production speeds, such as hot-tip gates and intricate cooling channels.

The typical unit cost at this stage varies between a few cents to $1 and the typical lead time is 4 to 6 months, due to the complexity of designing and manufacturing the mold.

Part 6

Useful resources

In this guide we touched on everything you need to get started with injection molding - but there’s plenty more to learn.

Here are the most useful resources on injection molding and other digital manufacturing technologies if you want to delve deeper.

Knowledge base

Here, we touched upon all you need to get you started with injection molding. There is plenty more to learn though in our Knowledge Base - a collection of technical articles on all manufacturing technologies, written by experts from Protolabs Network and the manufacturing industry.

Here is a selection of our most popular articles on injection molding:

Other guides

Want to learn more about digital manufacturing? There are more technologies to explore: